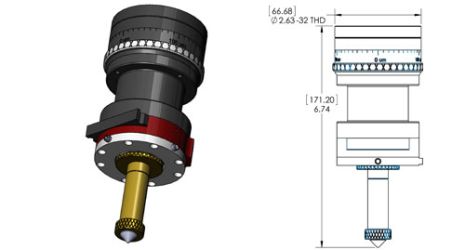

Micro Machining Head

Select the part number you need and click the button below to request a quote and more information.

-

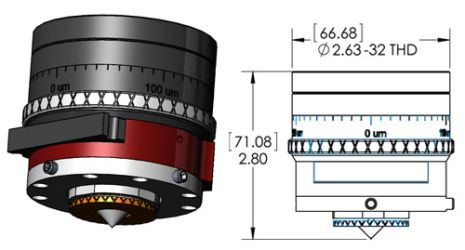

MMH-25-34-50: 50mm Focal Length Configuration - Base Unit

Overview & Specifications

The Micromachining Fiber Laser Process Head assembly is modular in design. It will accommodate focal lengths of 50mm, 60mm, 80mm, 100mm and 150mm. The base unit (MMH-25-34-50) is set-up for a 50mm f.l. The unit features provision for a 34mm diameter multi element focus lens set. +/- 4mm focus adjustment with 10um resolution. +/- 1.25mm X-Y nozzle tip adjustment with fine pitch adjusters. Cover glass cartridge with provision for 25mm x 3mm cover glass.,(Cover glass rated at 200psi). 1/8 BSPP tapped hole for process gas fitting. Quick-change laser process head mount. Anodized aluminum, stainless steel and brass construction.

Part Numbers

Part Number MMH-25-34-50

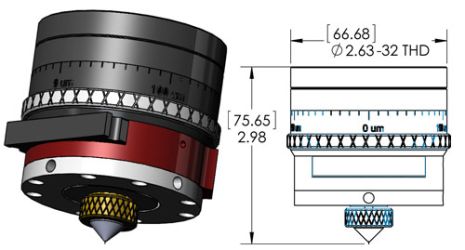

MMH-25-34-60: 60mm Focal Length Configuration

Overview & Specifications

Fiber Laser Process Head assembly configuration shows base unit with MMH-25-060-NE 60mm nozzle extension. The unit features provision for a 34mm diameter multi element focus lens set. +/- 4mm focus adjustment with 10um resolution. +/- 1.25mm X-Y nozzle tip adjustment with fine pitch adjusters. Cover glass cartridge with provision for 25mm x 3mm cover glass.,(Cover glass rated at 200psi). 1/8 BSPP tapped hole for process gas fitting. Quick-change laser process head mount. Anodized aluminum, stainless steel and brass construction.

Part Numbers

Part Number MMH-25-34-60

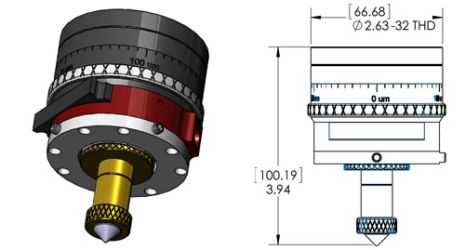

MMH-25-34-80: 80mm Focal Length Configuration

Overview & Specifications

Fiber Laser Process Head assembly configuration shows base unit with MMH-25-080-NE 80mm nozzle extension. The unit features provision for a 34mm diameter multi element focus lens set. +/- 4mm focus adjustment with 10um resolution. +/- 1.25mm X-Y nozzle tip adjustment with fine pitch adjusters. Cover glass cartridge with provision for 25mm x 3mm cover glass.,(Cover glass rated at 200psi). 1/8 BSPP tapped hole for process gas fitting. Quick-change laser process head mount. Anodized aluminum, stainless steel and brass construction.

Part Numbers

Part Number MMH-25-34-80

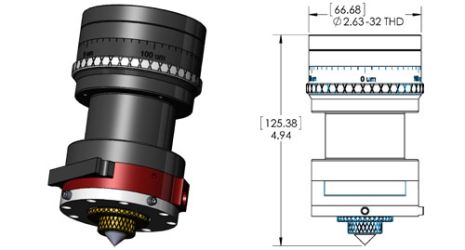

MMH-25-34-100: 100mm Focal Length Configuration

Overview & Specifications

Fiber Laser Process Head assembly configuration shows base unit with MMH-25-NBE nozzle body extension. The unit features provision for a 34mm diameter multi element focus lens set. +/- 4mm focus adjustment with 10um resolution. +/- 1.25mm X-Y nozzle tip adjustment with fine pitch adjusters. Cover glass cartridge with provision for 25mm x 3mm cover glass.,(Cover glass rated at 200psi). 1/8 BSPP tapped hole for process gas fitting. Quick-change laser process head mount. Anodized aluminum, stainless steel and brass construction.

Part Numbers

Part Number MMH-25-34-100

MMH-25-34-150: 150mm Focal Length Configuration

Overview & Specifications

Fiber Laser Process Head assembly configuration shows base unit with MMH-25-NBE nozzle body extension with MMH-25-150-NE 150mm nozzle extension. The unit features provision for a 34mm diameter multi element focus lens set. +/- 4mm focus adjustment with 10um resolution. +/- 1.25mm X-Y nozzle tip adjustment with fine pitch adjusters. Cover glass cartridge with provision for 25mm x 3mm cover glass.,(Cover glass rated at 200psi). 1/8 BSPP tapped hole for process gas fitting. Quick-change laser process head mount. Anodized aluminum, stainless steel and brass construction.

Part Numbers

Part Number MMH-25-34-150

Specifications subject to change without notice

Related Products

Fiber Series Products

MMH-25-34-50, MMH-25-34-60, MMH-25-34-80, MMH-25-34-100, MMH-25-34-150