- Laser Beam Delivery

- Custom Laser Systems

- Custom Machining

- Laser Delivery Optics

- Laser Beam Diagnostics

- Merged Technologies

- Events

- About Us

- Technical Center

Technical Center : Articles & Support

The technical library is an online resource for you to access technical articles about lasers, optics, laser beam delivery, diagnostics, and more.

-

Thermal Lensing Compensation (TLC)

Athermalization of focusing objectives is a common technique for optimizing imaging systems in the infrared where thermal effects are a major concern. The athermalization is generally done within the spectrum of interest and not generally applied to a single wavelength. By applying athermalization techniques to a laser system, a significant reduction in thermal lensing of the laser system can be realized. We describe a passive method minimizing thermal lensing of high power lasers.

-

Laser Beam Diagnostics: Theory of Operation

In every laser application, the laser beam profile provides valuable information for the most efficient use of the laser. By monitoring the laser beams spatial profile, circularity, centroid, astigmatism and M-squared values, you have early warning of any problems with the laser and entire beam delivery optical system. This relates to increased quality, process reliability, and reduced scrap.

-

Laser Beam Path Purge

One of the most important aspects of laser beam delivery for a high-power laser system is the beam purge. Beam purge can be defined as a low flow of clean, dry air or nitrogen that is introduced into the enclosed laser beam path. This flow of gas keeps a positive pressure inside the enclosed beam path to keep contaminants (particulate or vapors) out of the path of the laser beam.

Learn more about Laser Beam Path Conditioning for High-Power Laser Systems »

-

Technical Supplement: Cu/Ni/Au Mirrors

Haas Laser Technologies is one of the world's leading suppliers of metal mirrors for industrial laser applications. Advanced production techniques and specialized precious metal deposition processes have enabled us to develop a variety of sizes along with convex, concave, cylindrical and aspheric curvatures. Internal water cooling is available upon request.

-

Intelligent Laser Welding

The laser welding process requires monitoring of several parameters to ensure a good-quality, repeatable weld. This technology report was published in Industrial Laser Solutions Magazine.

-

Optical Cleaning (CVI)

Review the proper materials, techniques, and handeling procedures to minimize the risk of optical damage. Written by EmilyKubacki, published in Photonics Spectra.

-

Beam Delivery Basics

A laser beam delivery system is designed to safely deliver the laser beam to the workpiece with precision, accuracy, and stability in an industrial environment.

-

Manipulating Laser Beams

Optical laser wrists manipulate a laser beam around a workpiece to preform multidimensional laser processing. Previously available only with a complete turnkey laser system, these devices are now available separately for custom applications.

-

Precision Laser/Robot Cutting

Developments in laser technology and fiberoptic beam delivery have helped the Nd:YAG laser win a reputation as a viable, economic alternative in some cutting applications.

-

Precision Trepanning with a Fiber Laser

An analysis is developed to establish the optimal parameters for precision trepanning using a 200 watt fiber laser.

-

High Precision Refractive Scanner

Galvanometer scanners have been used for nearly three (3) decades for laser material processing. They are most commonly used for laser marking and have somewhat less utility in fine machining applications, in particular drilling precision holes and features below 250 microns.

-

Polarization

Polarization is an important optical property inherent in all laser beams. Brewster windows, reflective phase retarders, and absorbing thin-film reflectors use the advantage of polarization. On the other hand, it can cause troublesome and sometimes unpredictable results when ignored.

-

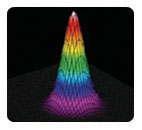

Beam Profiling

Lasers are ubiquitous in industry today. Carbon Dioxide, Nd:YAG, Excimer and Fiber lasers are used in many industries and a myriad of applications. Each laser type has its own unique properties that make them more suitable than others. Nevertheless, at the end of the day, it comes down to what does the focused or imaged laser beam look like at the work piece? This is where beam profiling comes into play and is an important part of quality control to ensure that the laser is doing what it intended to.

-

Optic Cooling

Choosing the correct coolant temperature is important to the proper operation and longevity of water-cooled optical components. When the coolant temperature is lower than the dew point, condensed water will build up on optical surfaces. This condition will lead to accelerated deterioration of the optical coatings.

Find what you were looking for?

Haas Laser Technologies specializes in custom-built high precision laser beam delivery components and systems. Contact a Haas Laser Technologies Sales Representative for more information.

Sign up for our

Quarterly Email Newsletter

Stay informed with laser industry news and new product releases

Check out our

Technical Center

Read white papers and articles, watch laser videos and learn more about optic design.

Haas Technical Center »