- Laser Beam Delivery

- Custom Laser Systems

- Custom Machining

- Laser Delivery Optics

- Laser Beam Diagnostics

- Merged Technologies

- Events

- About Us

- Technical Center

Additional Laser Beam Delivery Components

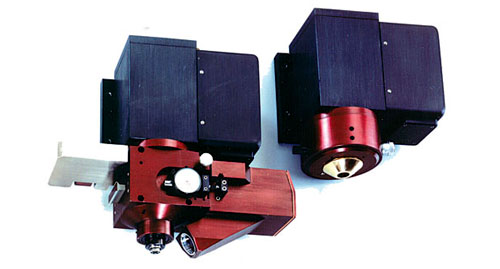

30º & 90º Trepan Head Systems

Designed for Nd:YAG or CO2 applications, our Trepan Head Systems have several focal length and angle combinations available. The whole lower assembly is rotated by a DC servo motor and toothed belt transmission. The unit rotates by command from the electronics interface unit. Rotation speed is entered via front panel digital control and held constant by a closed-loop motion controller system. Fine pitch adjustment screw and rotary indicator dial sets rotation radius.

Custom designed angled systems available.

30º Trepan Head Systems

Designed for Nd:YAG welding applications but can be modified for CO2. Fiber delivered Nd:YAG laser beam enters through fiber mount and recollimation housing. 90º kinematic bending mirror assembly directs laser beam to the process head. CCD camera system with X-Y axis and tip-tilt adjustments look at the workpicce through a zoom lens assembly.

Ultra-low light CCD camera transmits image to an adjustable crosshair generator and to a 9" B&W monitor. Laser beam, after being reflected by the kinematic bending mirror, is projected onto a cartridge loaded 90º bending mirror and then to a 30º bending mirror and then onto a 30mm dia. 60mm F.L. focus lens. The whole lower assembly is rotated by a DC servo motor and toothed belt transmission. The unit rotates by command from the electronics interface unit.

Rotation speed is entered via front panel digital control and held constant by a closed-loop motion controller system. Fine pitch adjustment screw and rotary indicator dial sets rotation radius up to 0.500". Self-compensating counter weight balances motion and eliminates vibration.

Custom angled systems available.

Additional options available upon request

We would be happy to discuss a custom designed solution that's right for any project, large or small. For additional information, contact a Haas Laser Technology sales representative today. (973) 598-1150

** Specifications subject to change without notice. Consult a Haas Laser Tech engineer for the latest specification changes or any additional assistance. **

Sign up for our

Quarterly Email Newsletter

Stay informed with laser industry news and new product releases

Check out our

Technical Center

Read white papers and articles, watch laser videos and learn more about optic design.

Haas Technical Center »