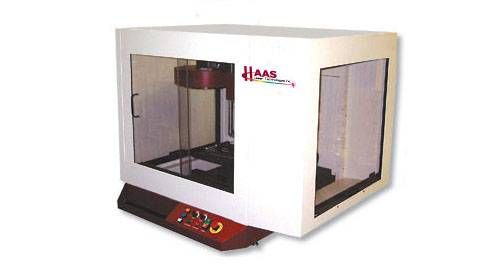

Custom Laser System

MLWS-1200 Micromachining Laser Workstation System

Features

- Granite co-polymer one-piece base and column

- Precision-ground cast iron table

- Linear ball bearing guideways for rigidity and accuracy

- covers on slideways and ball screws

- 18" X-Axis, 7" Y-Axis, 9.5" Z-Axis

- 360º Rotary Axis w/ 5C Collet

- 48" x 54" Footprint

- G&M code programming

- Scaling, rotation, mirroring, and subroutines

- Front operator panel for easy setups

- 32-bit DSP motion control card

- Windows XP operating system

- Unlimited program storage

- 4-axis simultaneous control

- CDRH Class 1 enclosure with interlocked door

- Laser safe viewing windows

- Enclosure light

- ISO 230 laser calibrated

Enclosure

The enclosure design utilizes extruded aluminum framework construction. The light-tight design with removable interlocked covers, panels and doors provide easy and safe access.

Internal lighting and laser safety window for visual inspection during the laser process are included with the ergonomic design. Complies with CDRH requirements as a Class 1 enclosure. The enclosure contains the complete laser head, laser beam delivery and motion system.

Laser

The laser including the laser head, power supply, laser control, and chiller are integrated into the system. The laser and wavelength are predetermined dependent upon the applications. Galvos and CCD cameras are some of the available options.

PC Controller

- PC Control of motion stages using Aerotech 3200 Series controller

- Rack mounted digital amplifier chassis with integral DC power supply and FireWire interface. Supports up to 6 axes of brush, brushless or stepper motor amplifiers

- 8 opto-isolated digital inputs and outputs, (4) 16 bit differential analog inputs (2) 16 bit analog outputs.

- Estop sense input

- Integration of laser operation & stages

- Control of optional galvo scanner head

- Control of shutter open & close

- CAD file download capability with the purchase of the optional Haas CAD/CAM software and A3200 post processor.

Motion System

The Motion System has the following specifications

Travel

X-Axis: 18" (457mm)

Y-Axis: 7" (178mm)

Z-Axis: 9.5" (241mm)

Rotary: 360º Continuous

Work Area

Table Size: 19.5" x 6.25" (495mm x 159mm)

Table Load: 150lbs (68kg)

Threaded Matrix: 3/8"-16, on 1" centers

Open Height: 12" (304mm)

Throat Clearance: 6.75" (171mm)

Rotary: 5C Collet

Axis Motors

Motors: DC Servo

Feed Rate: 0.1 - 200ipm (2 - 5080mm/min)

Rotary: 22rpm (upgradeable)

Accuracy

Linear Axis:

Positioning: ±0.0002" (5.08µm)

Repeatability: 0.0001" (2.54µm)

Resolution: 0.00002" (0.508µm)

Rotary Axis:

Positioning: ±20 arc sec

Repeatability: 4 arc sec

Resolution:

Dimensions

Width: 54" (1371mm)

Height: 56.5" (1435mm)

Depth: 48" (1219mm)

Weight: 475lbs (215kg)

Tooling & Fixturing: Available upon request

Integration

Complete implementation, fabrication, and system integration is performed by the staff engineers at Haas Laser Technologies, Inc. in Flanders, NJ

Documentation

Haas Laser Technologies, Inc. will provide a complete manual including all associated manuals.

Run-Off Criteria

Run-off criteria for equipment demonstration and acceptance must be pre-defined by customer prior to purchase order.

Demonstration

Demonstration, Training, and System acceptance will be performed at Haas Laser Technologies, Inc. in Flanders New Jersey. The fully integrated system will be demonstrated in the presence of the customer according to run-off criteria determined in advance. Haas Laser Technologies, Inc. will provide up to one (1) day for up to two (2) people for the process. The demonstration will familiarize the customer with the various system components, operation, and maintenance.

Installation

Onsite installation is available at a predetermined rate plus all expenses and subsistence.

Training-On-Site

On-Site training and laser process development is available at a predetermined rate plus all expenses and subsistence.

Contact us for information about this product