Laser Beam Diagnostics

Optimize Your Laser Systems with Accurate Diagnostics

Understand the key differences between the BA-CAM® and BWA-CAM® to choose the right tool for your needs. From profiling beam shape and size to analyzing beam propagation and quality, these diagnostic tools provide reliable, real-world data to help you fine-tune your laser systems for consistent performance.

BA-CAM and BWA-CAM Capabilities

An organized look at the Camera’s key functions and features. Click to learn how each supports your diagnostic needs.

Measure all beam characteristics

Leave no variable unknown. Measure all aspects of a laser beam instantly.

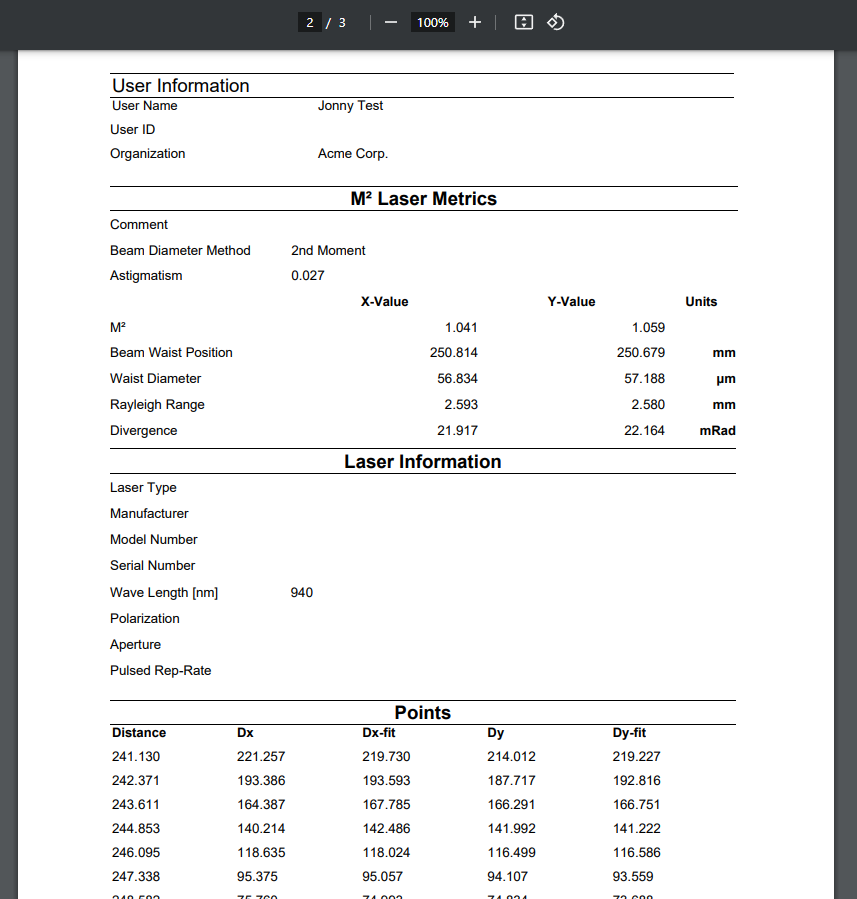

Measure every laser beam parameter

With our laser beam diagnostic systems, unlock a new level of understanding of all laser systems. Our technologies provide the capabilities to instantly measure all aspects of the beam quality, allowing the ability to accelerate discovery and research.

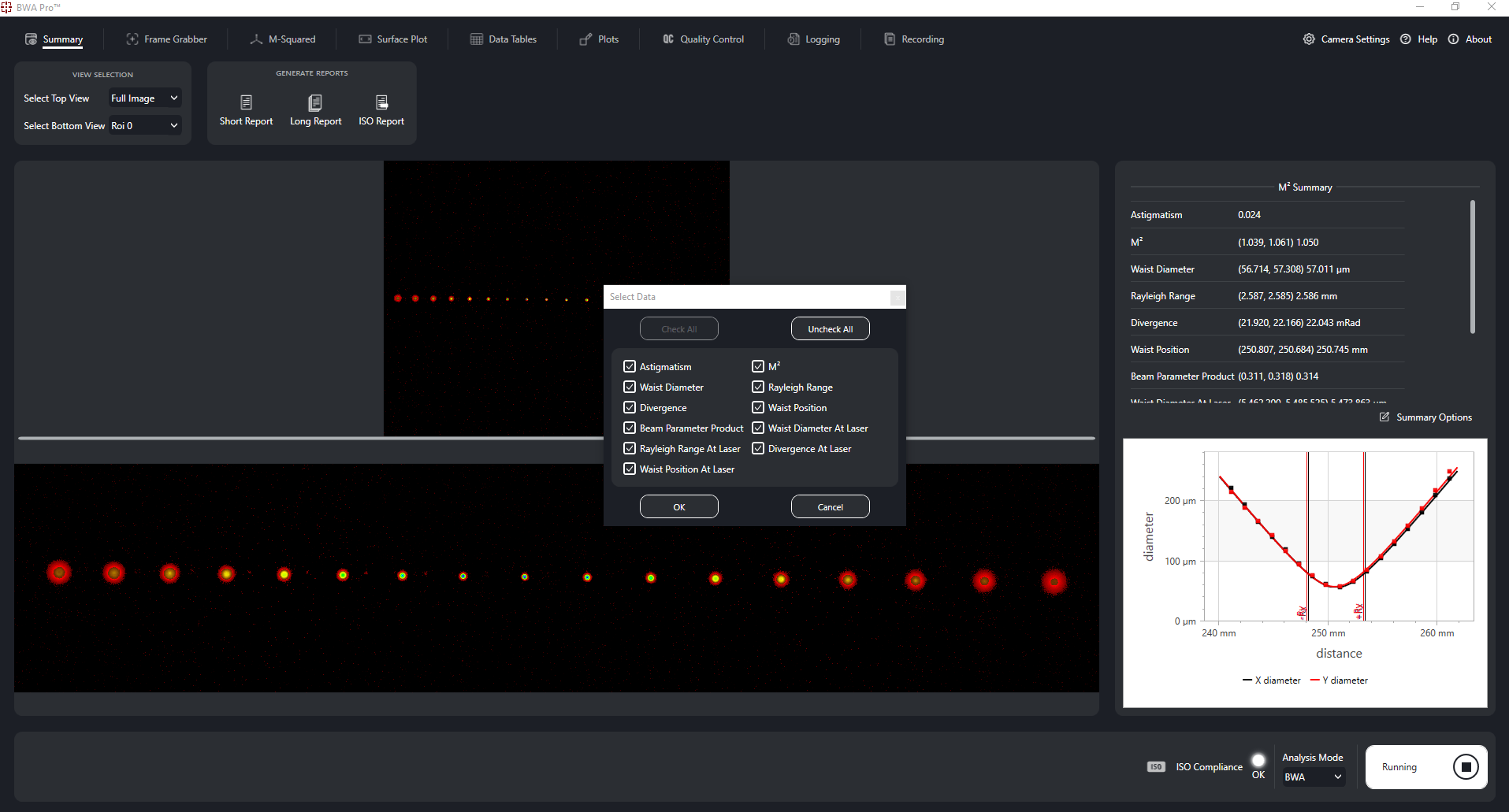

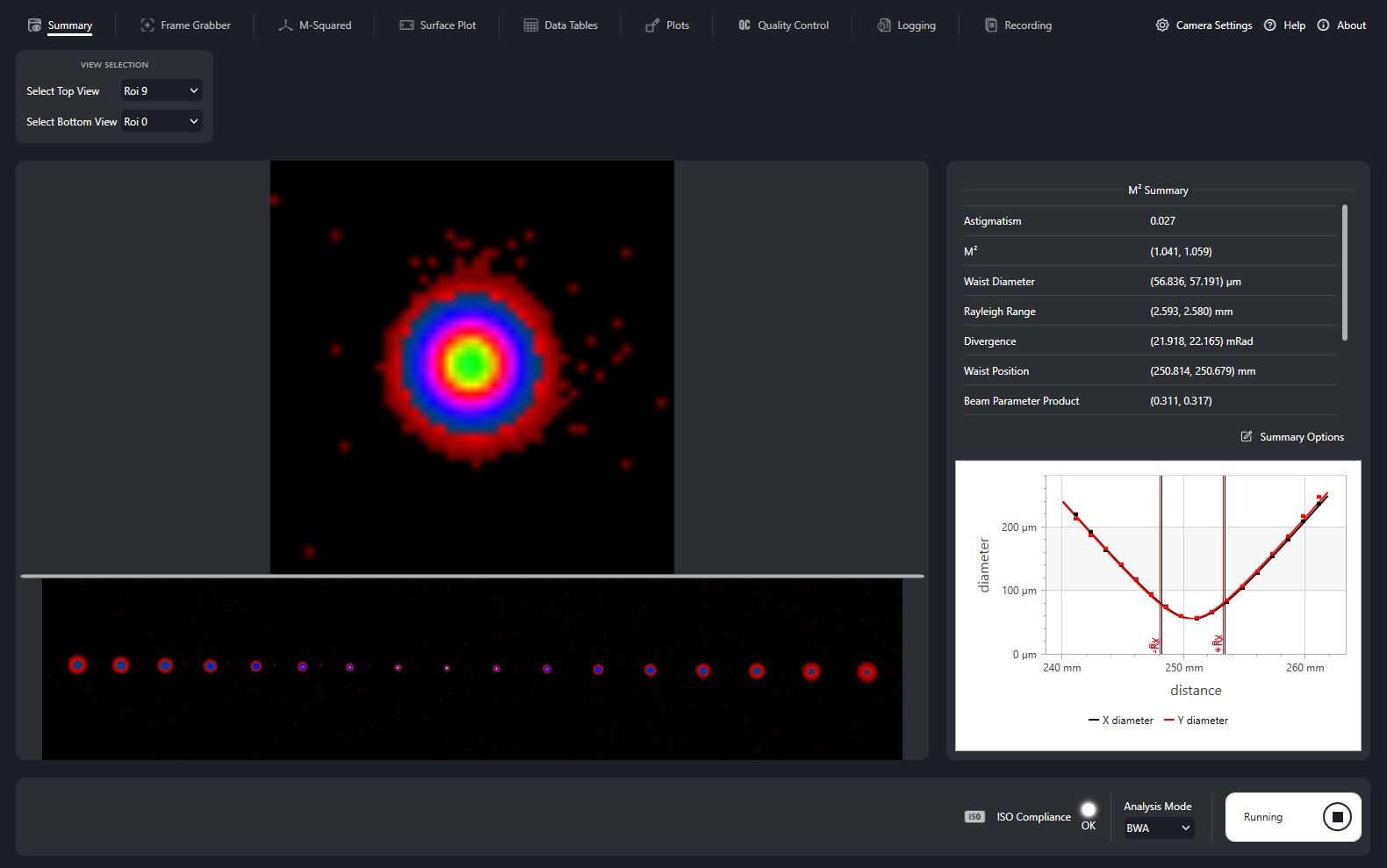

Below is a list of all parameters able to be logged in real time:

-

Astigmatism

-

Waist Diameter

-

Rayleigh Range

-

Divergence

-

Waist Position

-

Beam Parameter Product

-

Waist Diameter at Laser

-

Rayleigh Range at Laser

-

Waist Position at Laser

-

Divergence at Laser

-

Laser Power

Learn more about the BWA-CAM

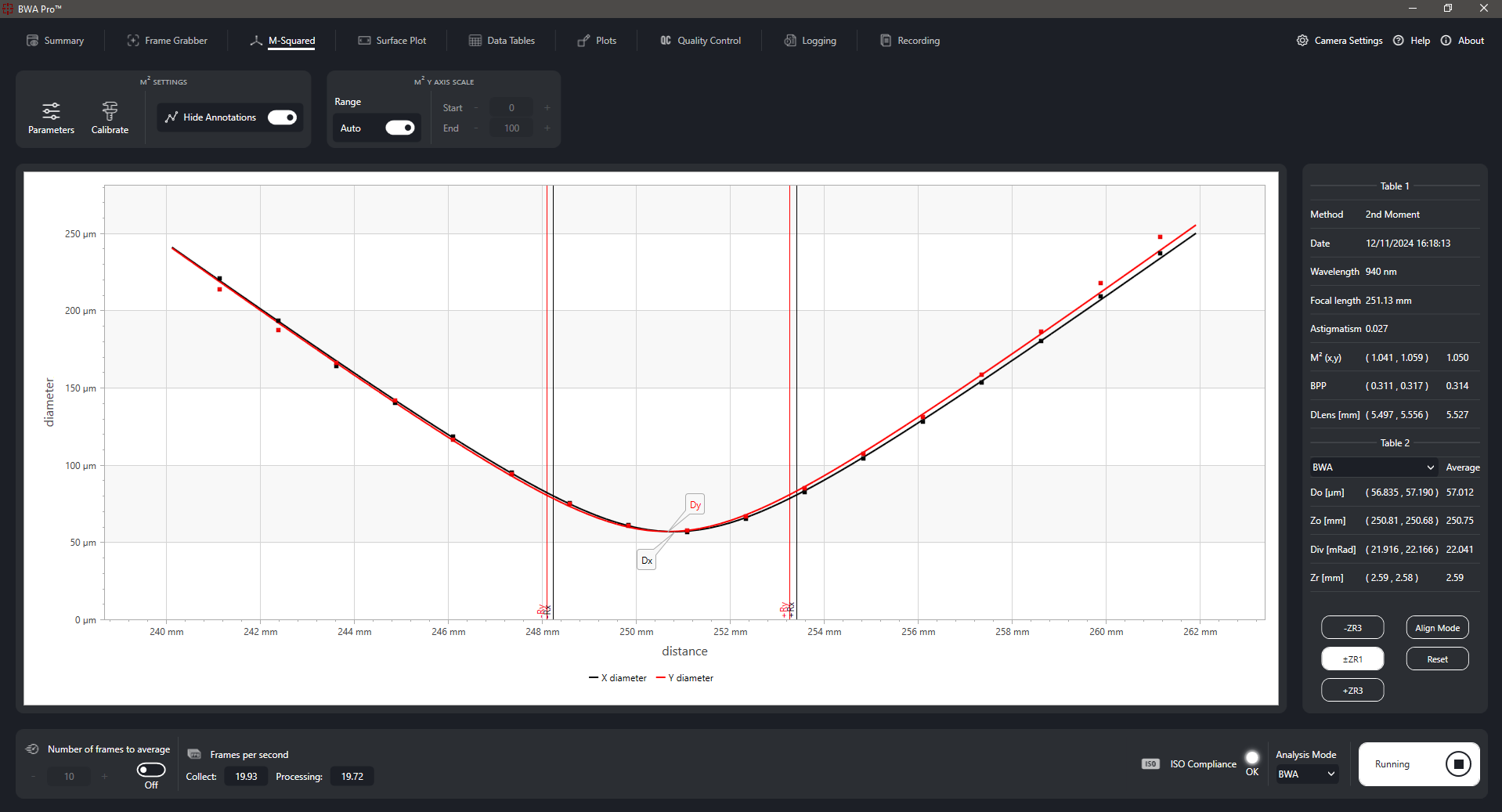

Single Pulse M-Squared Measurements

Instantly measure M-Squared in a single laser pulse with no moving components.

Single Pulse M Squared Measurements

Our patented technology allows users to measure M-squared with a single laser pulse, eliminating the need for moving parts found in traditional systems. This design increases accuracy, repeatability, and measurement speed, ensuring consistent results with minimal setup adjustments.

With the ability to perform real-time M² measurements, users can monitor beam quality during dynamic experiments or while making adjustments to optical setups. This capability simplifies workflows and provides immediate, reliable data making it ideal for detailed laser characterization in academic and experimental environments.

Learn more about the BWA-CAM

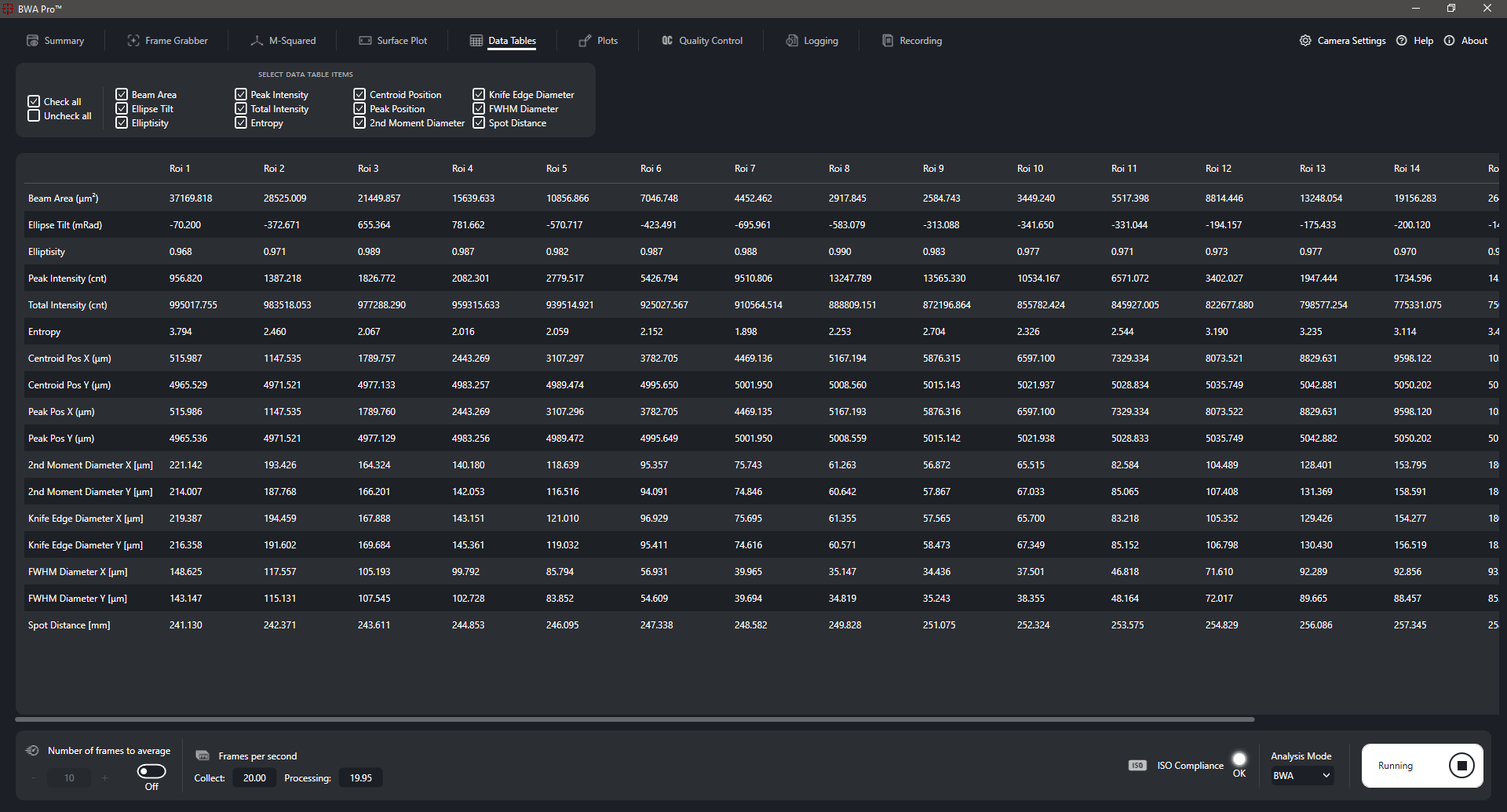

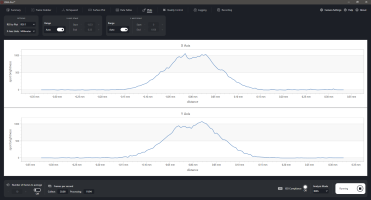

Real Time Data Acquisition

Real Time Data Acquisition

Provides the ability to monitor key laser beam parameters in real time, including waist position, focused spot size, M², and ellipticity. This live feedback allows for immediate adjustments and detailed analysis, enabling precise control over beam quality during experiments.

With customizable charts and graphs, users can tailor the interface to display the parameters most relevant to their research. Select specific metrics to log over time and export the data as a CSV file for further analysis or documentation. This flexibility makes it easy to visualize trends, compare results, maintain accurate records and streamline data management.

Click below to learn more about the BWA-CAM

Real time tracking of Thermal Lensing

Eliminate uncertainty in thermal lensing and focus position with real-time tracking. Accurately measure thermal lensing shifts as it occurs in real time.

Real time tracking of Thermal Lensing

Measure and record focus lens shifts in real time, providing critical data for evaluating lens design. This capability helps identify and mitigate thermal lensing effects, ensuring the proper selection of lens substrates to minimize beam distortion and maintain performance. By understanding how lenses respond under operational conditions, researchers can optimize designs for stability and reliability in a wide range of applications.

Learn more about the BWA-CAM

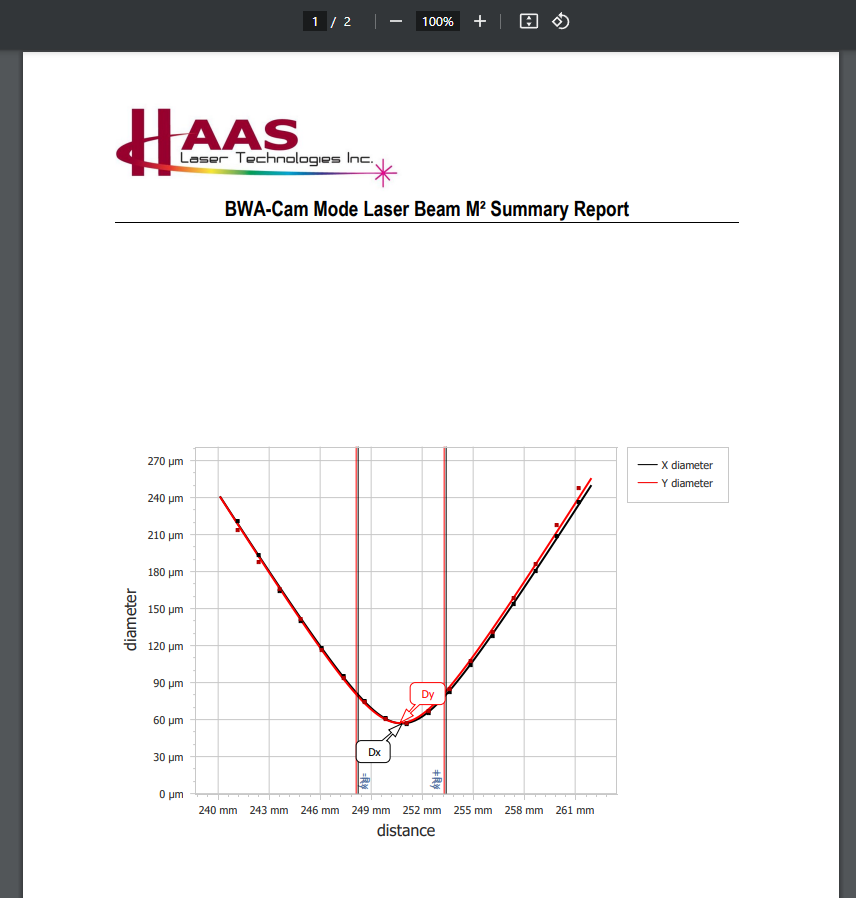

Full Caustic Measurement over 3 Rayleigh Lengths

Real-time measurement of the full beam caustic over three Rayleigh lengths on a single sensor, fully compliant with ISO 11146 and ISO 13694 standards.

Full Caustic Measurement over 3 Rayleigh Lengths

Measure the full beam caustic in real time across three Rayleigh lengths, using a single sensor in compliance with ISO 11146 and ISO 13694 standards. This comprehensive measurement method provides greater accuracy and insight into the beam’s propagation and focus characteristics.

Thermal lensing effects are captured directly in the caustic measurement, offering a clear view of how the beam behaves under real-world conditions. By using this method, researchers can better evaluate and optimize beam quality for their specific applications.

Learn more about the BWA-CAM

Measure from Milliwatts to Kilowatts

Measure laser powers from less than 1 mW to over 50 kW, accommodating a wide range of applications.

Measure from Milliwatt to Kilowatt

The system is designed to handle a wide range of laser powers, from less than 1 mW to over 50 kW, using a modular ecosystem of components. With options for attenuation, beam dumps, and other accessories, the system can be configured to suit virtually any power level or application.

This modular design ensures seamless integration with other Haas Laser Technologies components, creating a flexible and efficient solution for managing laser power. Whether working with low-power experimental setups or high-power industrial systems, the tools fit together to provide consistent and reliable performance.

Learn more about the BWA-CAM

Real Time QC Tracking

The system provides real-time tracking of multiple quality control parameters, offering a powerful tool for monitoring and maintaining laser performance. Users can customize the selection of parameters they want to monitor, such as waist position, M², beam diameter, divergence, ellipticity, and more, tailoring the interface to focus only on what matters most for their application.

Each parameter can be assigned upper and lower limits, ensuring that any values falling outside the defined range trigger an output through an I/O interface. This enables automated responses, such as activating interlocks or initiating corrective actions, to maintain safety and operational consistency.

Learn more about the BWA-CAM

Integrated Power Meter Function

The integrated power meter function allows you to measure laser power in real time alongside other beam parameters, all within the same system. Once calibrated, this functionality eliminates the need to switch tools during your process, providing a seamless and efficient way to gather comprehensive data.

Power measurements can be logged over time, visualized in customizable charts, and exported as a CSV for further analysis. Additionally, the power data integrates directly into real time QC tracking.

This integration simplifies workflows while maintaining precise control, ensuring all critical parameters are monitored simultaneously for complete oversight of your laser systems.

Learn more about the BWA-CAM

Instant Measurements

All selected laser characteristics can be measured at the same time with a single pulse.

Instant Measurements

By utilizing the trigger cable, the system synchronizes laser pulses with the camera, allowing for instant capture of measurements. This functionality ensures precise timing and accuracy, making it ideal for pulsed laser applications, including picosecond and femtosecond lasers.

All selected parameters can be displayed simultaneously, tailored to the specific needs of your application. Whether monitoring M², waist position, etc, this real-time capability provides comprehensive insight, eliminating the delays seen in traditional data aquisition.

Designed for high-speed laser systems, this feature delivers reliable and immediate results, supporting advanced research and industrial applications with demanding pulse requirements.

Learn more about the BWA-CAM

Data Privacy

Ensure data privacy with our standalone desktop application, designed for secure, offline operation without external communication.

You own all your data.

Data Privacy

Our software is a standalone desktop application that you download and install on your computer, operating entirely offline. It has no capability to communicate with external software unless physically connected for specific I/O functions. This design ensures that sensitive data remains within your secure environment, aligning with data protection best practices and supporting compliance with data privacy regulations.

By maintaining an isolated system, you can confidently manage your laser diagnostics without concerns about unauthorized data access or breaches. This approach is particularly beneficial for organizations handling confidential information, as it minimizes exposure to external threats and enhances overall data security.

Learn more about the BWA-CAM

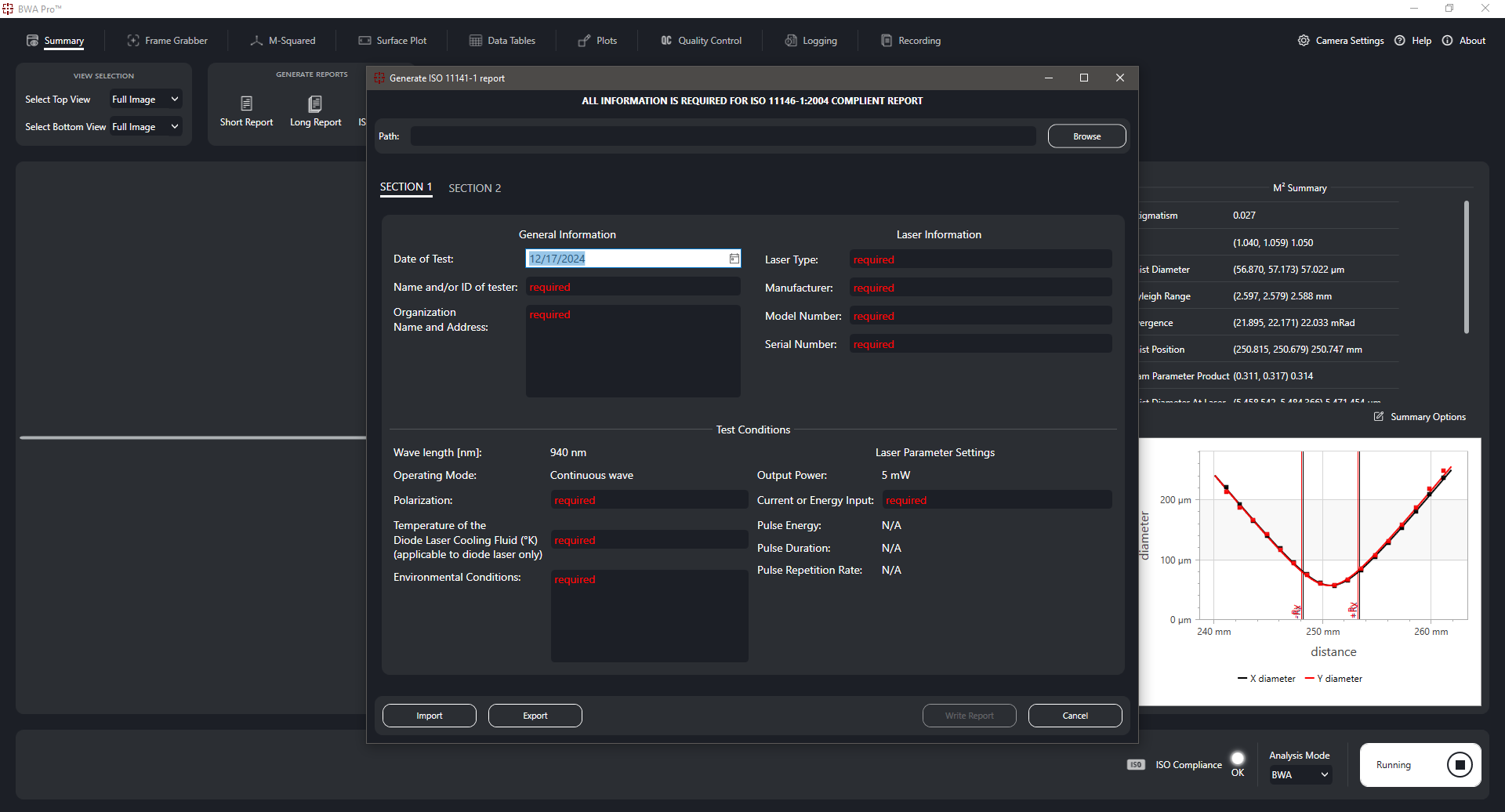

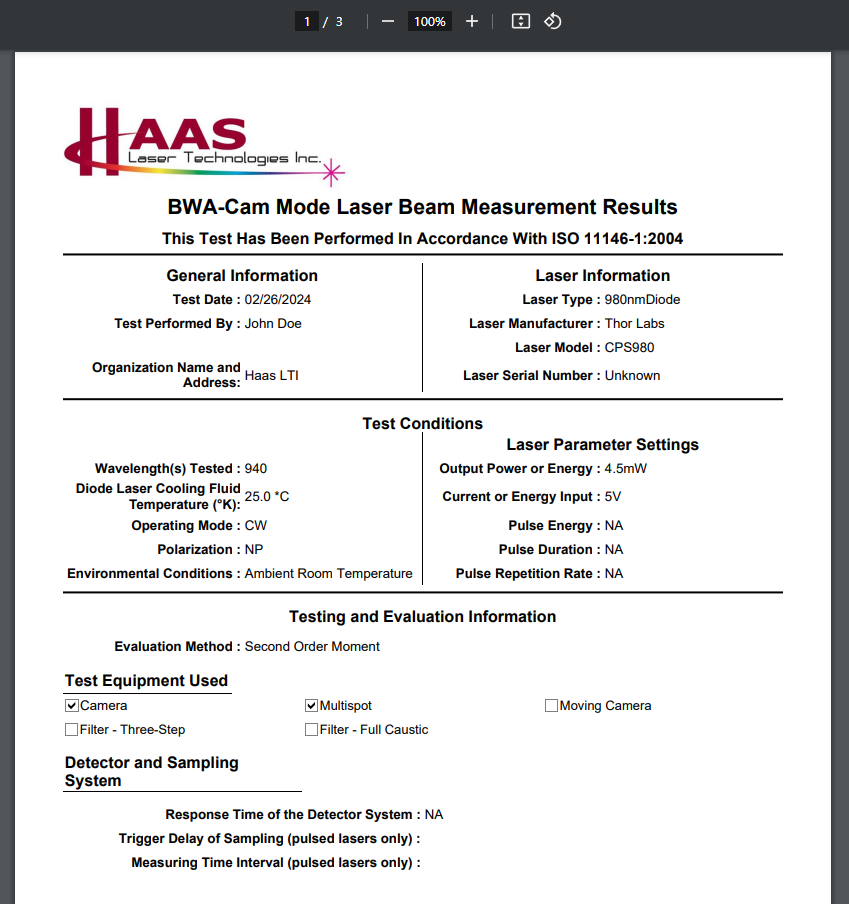

Multiple Reporting Options

Choose from four reporting options—short, long and ISO compliant reports, to meet your specific data analysis needs.

Multiple Reporting Options

Our software offers three distinct reporting options to accommodate various documentation and analysis requirements:

- Short Report: Provides a concise summary of key beam parameters.

- Long Report: Includes a detailed breakdown of measurements and additional metrics for in-depth analysis.

- ISO Report: Generates data formatted to comply with ISO 11146 and ISO 13694 standards.

With these customizable reporting options, users can select the format that best fits their application, ensuring clarity, compliance, and thorough documentation of beam diagnostics.

Learn more about the BWA-CAM

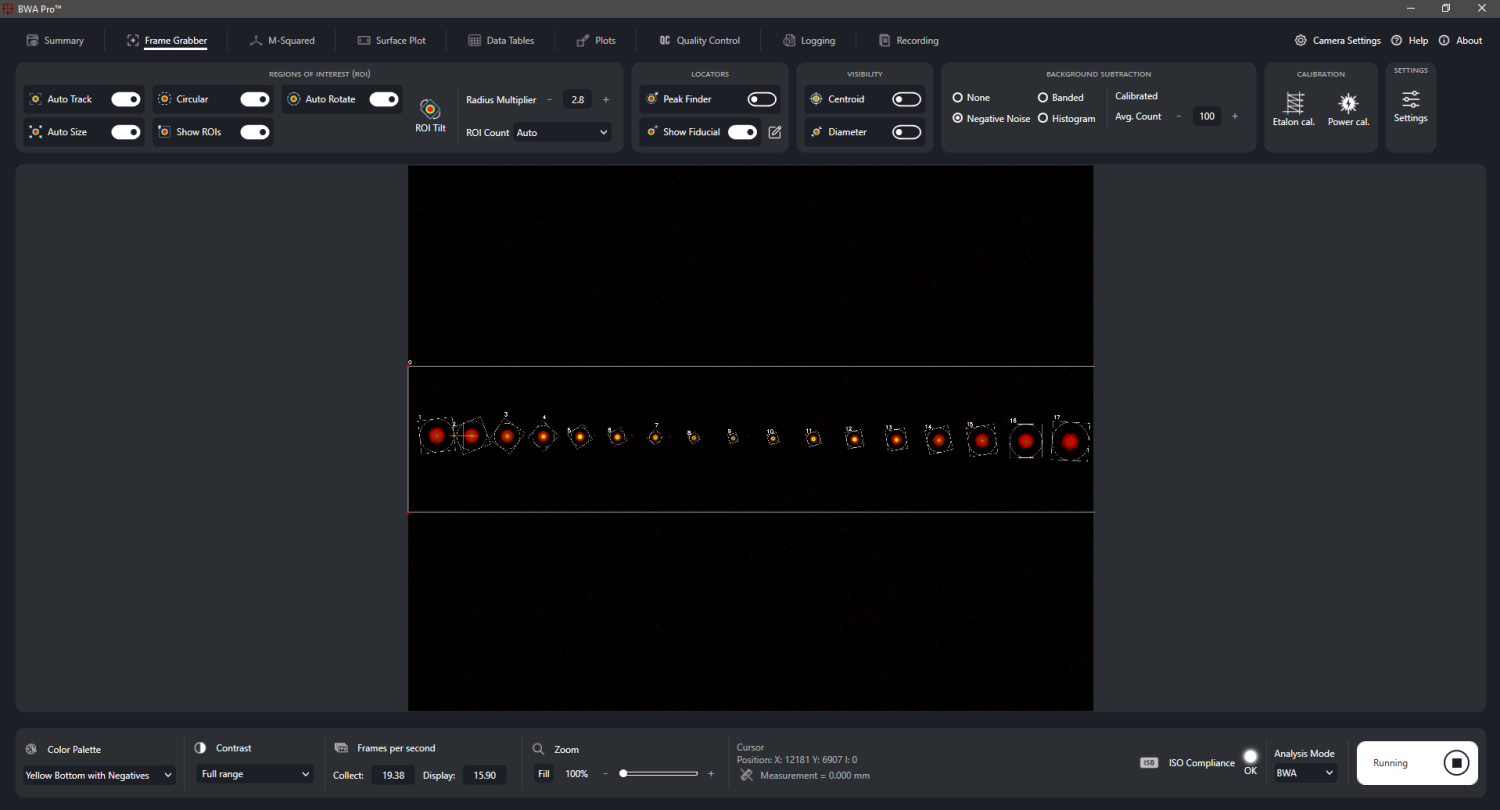

Real Time Alignment

The real-time camera feed allows users to observe and dynamically adjust laser spot shape, size, astigmatism, etc. By providing live feedback across the near field, beam waist, and far field, the system enables precise alignment changes with immediate visual confirmation.

This feature is particularly useful for aligning laser cavities and optimizing the entire optical beam path in real time. Whether you're fine-tuning optical alignment for research, manufacturing, or system setup, this capability ensures optimal beam quality and minimizes downtime during adjustments.

Learn more about the BWA-CAM

BA-CAM and BWA-CAM Comparison

Below is a detailed, side-by-side comparison of the BA-CAM and BWA-CAM.

Feature Comparision

| Features | BA-CAM | BWA-CAM |

|---|---|---|

|

Beam profile measurment |

Single spot cross section profile of a laser beam |

Multi spot (Full Caustic) cross section profile of a laser beam |

|

M2 Measurement |

Achieved by moving the camera through the full beam focus/beam caustic |

Patented technology allows for instant full beam focus/beam caustic with no moving components |

|

Attenuation |

Wide range of options low power, mid power and high power |

Nominal -4 to -5 OD for low power and a wide range of options for mid to high power |

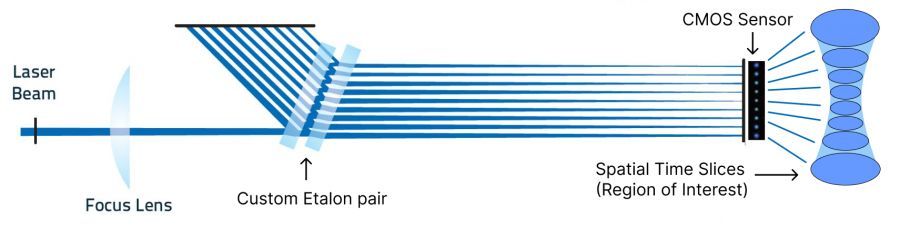

Patented Technology Overview

Measuring the beam profile using Spatial Time Slices

The BWA-CAM utilizes a unique method to analyze the laser beam by creating spatial time slices. This is achieved without the need for any moving mechanical parts, which is a significant advancement over traditional beam analysis methods that require mechanically moving scanning components along the beam caustic.

Real Time M-Squared Measurements

|

The spatial time slices generated by the custom etalon pair are captured by a high-speed CMOS sensor, which has been adapted by removing the window to eliminate any interference effects. This sensor setup enables the BWA-CAM to provide rapid feedback on the beam's properties, facilitating real-time analysis. |

||

|

The BWA-CAM represents a significant leap in laser beam analysis technology. By employing a pair of custom etalons to create spatial time slices of the focused beam, this patented analyzer eliminates the need for moving parts, thereby enhancing reliability and enabling real-time, accurate M-square measurements at the frame rate of the camera or in a single laser pulse. This approach not only simplifies the process of laser beam analysis but also provides critical insights into the beam's properties with unprecedented speed and precision, essential for optimizing laser applications in various industrial settings. |

Explore the Beam Diagnostic Cameras

BA-CAM

Beam Analyzer CAMera

- Single spot measurment

Learn more about the BA-CAM and its configurations

BWA-CAM

Beam Waist Analyzer CAMera

- Multi spot measurment

Learn more about the BWA-CAM and its configurations

BWA-PRO Software

Control Software

- Control software for use with BA-CAM and BWA-CAM

Learn more about the BWA-PRO software and its features