- Laser Beam Delivery

- Custom Laser Systems

- Custom Machining

- Laser Delivery Optics

- Laser Beam Diagnostics

- Merged Technologies

- Events

- About Us

- Technical Center

BWA-MON® (Galvo Input)

Product Overview

3D Laser Additive Manufacturing (LAM) has developed as a new method to manufacture components which typically couldn’t previously be manufactured by traditional machining or material removal methods.

While Laser Additive Manufacturing is now capable of providing high quality components, many processes must also comply to DOD and FDA standards. This starts with traceable laser beam measurement and certification before, during and after the manufacturing process

The Beam Waist Analyzer Camera (BWA-CAM®) for 3D Additive manufacturing enables “real-time” laser beam measurement with “no moveable parts” for analysis and monitoring of high power CW and pulsed lasers. The above 3D Additive Manufacturing modular configuration includes the following technologies:

The Haas LTI Beam Waist Analyzer Camera (BWA-CAM®) system provides ISO 11146 and ISO 13694 measurements to measure the “real-time” laser beam spatial metrics such as:

- M2, K and BPP values

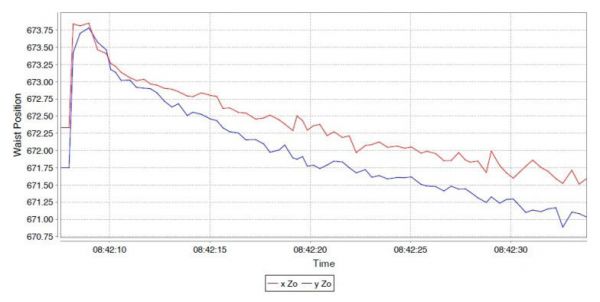

- Beam Waist size and location

- Spatial profile

- Focus shift

- Divergence

- Circularity

- Rayleigh Length

- Astigmatism

- Centroid

Thermal lensing measurement log of 1 kW, 3-D based galvo system.

The Haas Laser Beam Analyzer System design contains no “moving components” and provides instantaneous measurements and analysis of the laser beam and all active optical elements. While other “real time” systems show a simulated outside “shell” of the beam, our patented design provides both 2-D and 3-D profiles of the beam through more than one Rayleigh range. In our system, you always know what your beam looks like and where it is located.

The Coherent PowerMax Pro Power® Sensor enables direct NIST-traceable, highly accurate absolute laser power measurements. The device utilizes their new patented transverse thermoelectric detector technology which combines the broad wavelength sensitivity, dynamic range and laser damage resistance of a thermopile with the response speed of a semiconductor photodiode.

RELATED PRODUCT: BD-3D-1K-A Beam Dump

BWA-PRO Software included

BWA-PRO control software included with lifetime access for this product.

Not sure if this is the right product for your application?Send us an email or give us a call, we are happy to help. |

Sign up for our

Quarterly Email Newsletter

Stay informed with laser industry news and new product releases

Check out our

Technical Center

Read white papers and articles, watch laser videos and learn more about optic design.

Haas Technical Center »