Fiber lasers have transformed industrial manufacturing, offering precision, power, and efficiency in applications like cutting, welding, marking, and engraving. But what exactly is a fiber laser, and how does it compare to other laser types? In this guide, we’ll break down how fiber lasers work, their key advantages, and the best applications for them.

What is a Fiber Laser?

A fiber laser is a type of solid-state laser that generates and delivers its beam through optical fibers rather than traditional gas-filled tubes or crystal-based media. This design makes fiber lasers highly efficient, compact, and capable of producing extremely precise beams for a wide range of industrial applications.

The word LASER stands for Light Amplification by Stimulated Emission of Radiation, and the first laser was built in 1960 by American engineer and physicist Theodore H. Maiman. However, just a year later, Elias Snitzer demonstrated the first optical fiber laser and fiber amplifier, laying the foundation for today’s fiber laser technology. Unlike CO₂ lasers, which use a gas mixture to generate light, or Nd:YAG lasers, which rely on crystal rods, fiber lasers use a fiber-optic cable doped with rare-earth elements to amplify the laser beam. This advancement has led to superior energy efficiency, low maintenance, and exceptional beam quality, making fiber lasers a staple in industries ranging from manufacturing and medicine to telecommunications.

How Does a Fiber Laser Work?

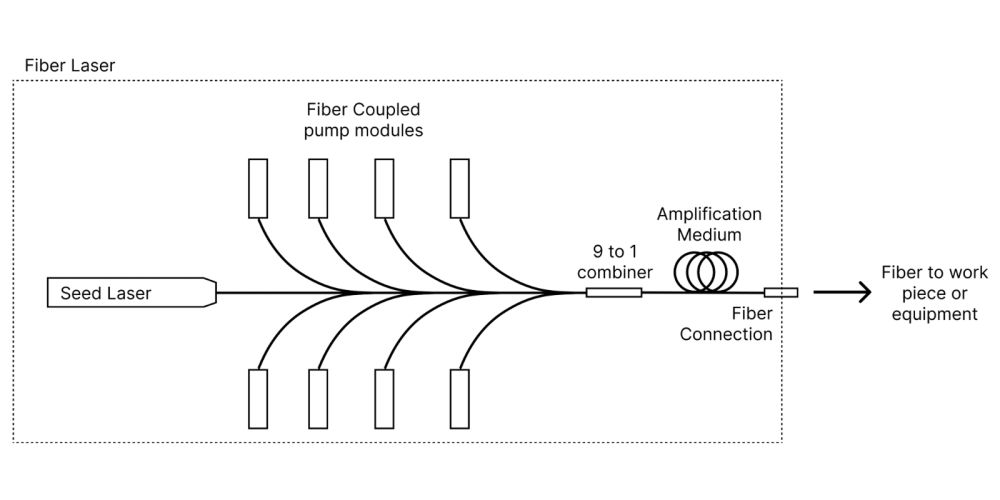

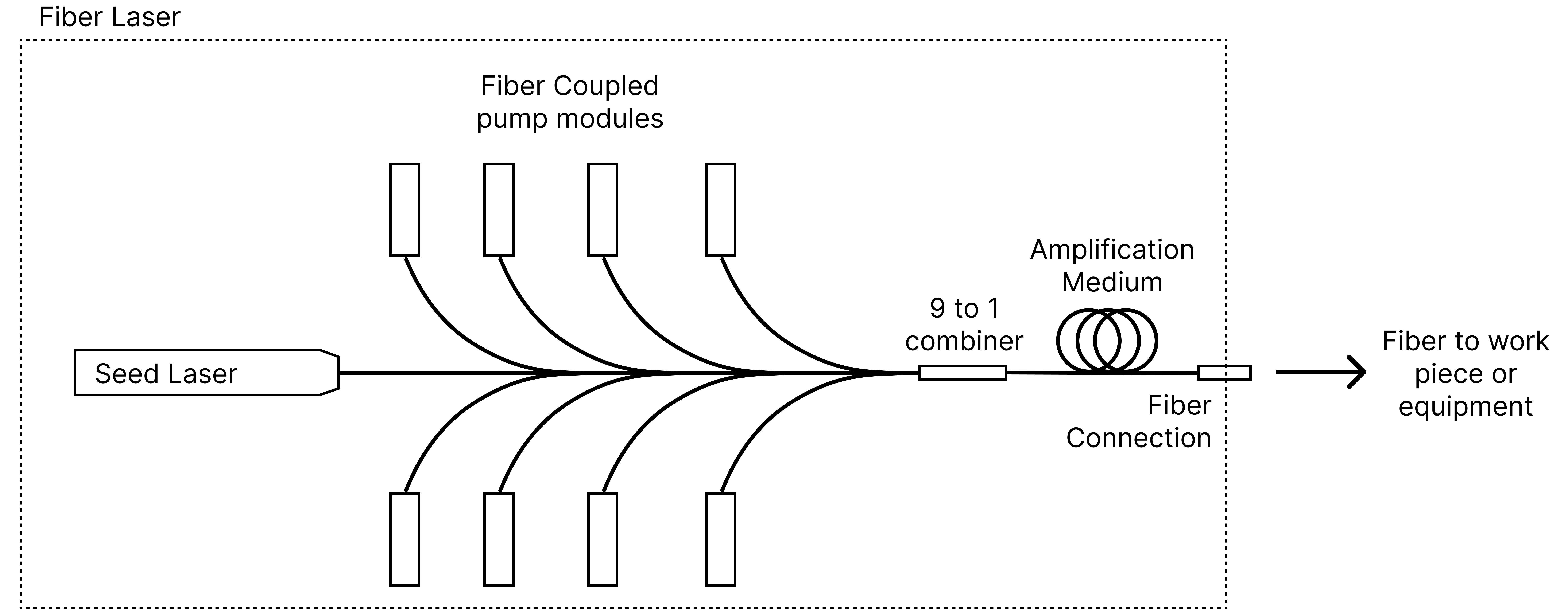

A fiber laser system is more than just a single fiber—it consists of multiple critical components that work together to generate, amplify, and deliver a high-power, high-quality laser beam. Let’s break down the main elements: the seed laser, fiber pump modules, combiner, amplification stages, and fiber connector. Below is a diagram of the concepts of a fiber laser and how they relate to each other.

1. Seed Laser: The Initial Light Source

The seed laser is where it all begins. This is a low-power, highly stable laser source that generates an initial beam, which will later be amplified to higher power levels. The seed laser typically operates at a specific wavelength (e.g., 1064 nm for ytterbium-doped fiber lasers) and provides a clean, narrow-band signal that forms the foundation of the final laser output.

- Types of Seed Lasers:

- Continuous Wave (CW) seed lasers for applications requiring steady output.

- Pulsed seed lasers for high-peak power applications like marking and micromachining.

2. Fiber Pump Modules: Injecting Energy

Once the seed laser generates the initial beam, it needs more power. This is where fiber pump modules come in. These modules contain high-power diode lasers that inject energy into the fiber, exciting the rare-earth dopants (like ytterbium) inside the fiber core. This process is known as optical pumping and is essential for amplifying the laser beam.

- Key Features:

- Pump diodes operate at specific wavelengths that efficiently excite the doped fiber.

- Multiple pump modules may be used to achieve higher power levels.

- Pump light is typically coupled into the fiber through wavelength-selective components.

3. Combiner: Merging Multiple Pump Sources

To maximize efficiency, fiber lasers often require multiple pump modules working together. These pump sources need to be combined and injected into the active fiber, which is done using a fiber combiner. The combiner is a passive optical component that merges pump light from several diodes into a single fiber, ensuring uniform distribution of pump energy.

- Why It’s Important:

- Enables higher power levels by combining multiple pump sources.

- Ensures efficient energy transfer to the doped fiber core.

- Improves laser stability by balancing the input power across different pump diodes.

4. Amplification: Powering Up the Beam

The most critical stage in a fiber laser system is amplification. The weak beam from the seed laser passes through an active fiber, which is doped with rare-earth elements (like ytterbium or erbium). When pumped with energy from the fiber pump modules, this fiber amplifies the signal to much higher power levels through a process called stimulated emission.

- Stages of Amplification:

- Pre-Amplifier – Boosts the weak seed laser to a moderate power level.

- Main Amplifier – Further amplifies the laser beam to high power (often kilowatts in industrial lasers).

- Power Amplifier (if needed) – Used in ultra-high-power systems for applications like metal cutting and welding.

By carefully controlling the amplification process, fiber lasers achieve high beam quality with minimal distortion.

5. Fiber Connector: Delivering the Laser Beam

Once the laser beam is fully amplified, it needs to be delivered to the workpiece or application. This is done using a fiber connector, which ensures efficient and stable beam transmission. The fiber connector links the laser output to the beam delivery system, such as a cutting head, welding optics, or scanning system.

- Key Features of Fiber Connectors:

- High-power connectors must handle extreme optical intensities without damage.

- Precision alignment ensures minimal beam loss and high efficiency.

- Different connector types exist, including QBH (for high-power applications) and SMA (for lower-power fiber lasers).

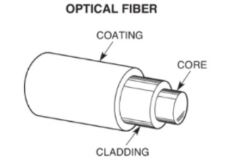

Understanding the Fiber Structure in a Fiber Laser

The core component of a fiber laser system is, of course, the fiber itself. But not all optical fibers are the same—fiber lasers use specialized doped optical fibers designed for high-power laser amplification and beam transmission. These fibers have multiple layers, each playing a critical role in guiding, protecting, and amplifying the laser beam. Let’s break it down:

1. Core: The Heart of the Fiber

At the center of the optical fiber is the core, where the laser light is transmitted and amplified. This core is doped with rare-earth elements like ytterbium (Yb), erbium (Er), or neodymium (Nd), which provide the gain medium necessary for laser amplification.

-

Function:

- The core is where the stimulated emission process occurs, amplifying the seed laser beam.

- It must be precisely designed to support single-mode or multi-mode beam propagation, depending on the laser’s application.

-

Doping Materials & Their Wavelengths:

- Ytterbium (Yb) → 1030-1100 nm (common in cutting and welding lasers)

- Erbium (Er) → 1530-1620 nm (used in telecommunications)

- Neodymium (Nd) → 1064 nm (similar to YAG lasers, used in marking and engraving)

The core size determines the beam quality—smaller cores (single-mode fibers) produce high-quality, tightly focused beams, while larger cores (multi-mode fibers) can handle higher power but with slightly lower beam precision.

2. Cladding: Controlling Light Propagation

Surrounding the core is the cladding, which plays a crucial role in keeping the laser beam confined within the fiber through total internal reflection (TIR).

-

Function:

- The cladding ensures that light stays inside the core and propagates efficiently.

- It works by having a lower refractive index than the core, forcing the laser beam to reflect inward instead of escaping.

-

Double-Clad Fiber Design:

- Many high-power fiber lasers use a double-clad fiber, which has:

- Inner cladding (higher index, directly around the core)

- Outer cladding (lower index, surrounding both the core and inner cladding)

- This design allows pump light from fiber pump modules to enter the fiber through the cladding, ensuring better absorption and higher efficiency.

- Many high-power fiber lasers use a double-clad fiber, which has:

3. Coating: Protecting the Fiber

The coating is the outermost layer of the fiber, designed to provide mechanical strength and environmental protection.

-

Function:

- Shields the fiber from physical damage, dust, and moisture.

- Helps manage the fiber’s thermal stability, especially in high-power laser applications.

- Absorbs external mechanical stress to prevent microscopic cracks that could degrade performance over time.

-

Materials Used:

- Acrylate coating (standard for lower-power applications)

- Polyimide coating (used for high-temperature environments)

- Metal coatings (gold, aluminum) (used for extreme conditions, aerospace, or medical applications)

In industrial fiber lasers, the coating also plays a role in ensuring the fiber can handle high bending tolerances, which is crucial when routing laser beams through complex beam delivery systems.

Putting it all together

Fiber lasers represent a breakthrough in laser technology, combining efficiency, precision, and durability into a compact, maintenance-friendly system. At their core, these lasers rely on a seed laser to generate an initial beam, which is then amplified through doped optical fibers using energy from fiber pump modules. This amplification process is made possible by stimulated emission, where the rare-earth elements in the fiber core boost the laser’s power while maintaining exceptional beam quality.

The fiber itself plays a crucial role in ensuring efficient light transmission. The core, doped with elements like ytterbium or erbium, serves as the amplification medium, while the cladding keeps the laser light confined through total internal reflection. The outer coating protects the fiber from external damage and thermal stress, ensuring long-term reliability in demanding applications.

By eliminating the need for external mirrors and complex alignment systems, fiber lasers achieve high optical efficiency, low energy loss, and superior stability. Their modular design allows for scalability, making them suitable for a range of power levels, from low-power precision tasks to high-power industrial applications.

Ultimately, fiber lasers stand out for their ability to deliver a high-intensity, precisely controlled laser beam with minimal maintenance and maximum efficiency. Their advanced engineering ensures they remain at the forefront of laser technology, continuously evolving to meet the demands of modern industry.

Industrial Laser Components

Haas Laser Technologies designs high-performance beam delivery components for cutting, welding, and drilling applications. We also offer custom solutions and expert consulting to help you with every step of your laser processing project or product.

- Beam Delivery Components

- Laser Optics

- Beam Diagnostic Tools

- Custom Laser Systems