While Laser Additive Manufacturing is now capable of providing high quality components, many processes must also comply to DOD and FDA standards. This starts with traceable laser beam measurement and certification before, during and after the manufacturing process

The Beam Waist Analyzer Camera (BWA-CAM) for 3D Additive manufacturing enables “real-time” laser beam measurement with “no moveable parts” for analysis and monitoring of high power CW and pulsed lasers. The above 3D Additive Manufacturing modular configuration includes the following technologies:

The BWA-CAM system provides ISO 11146 and ISO 13694 measurements to measure the “real-time” laser beam spatial metrics such as:

- M2, K and BPP values

- Beam Waist size and location

- Spatial profile

- Focus shift

- Divergence

- Circularity

- Rayleigh Length

- Astigmatism

- Centroid

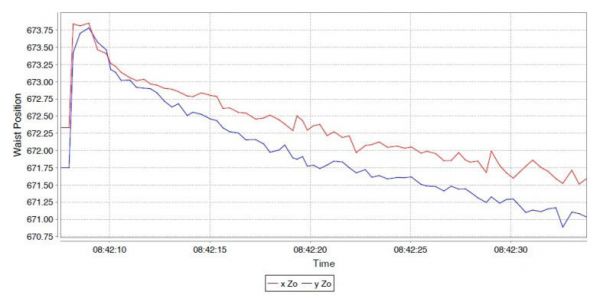

Thermal lensing measurement log of 1 kW, 3-D based galvo system.

The Haas Laser Beam Analyzer System design contains no “moving components” and provides instantaneous measurements and analysis of the laser beam and all active optical elements. While other “real time” systems show a simulated outside “shell” of the beam, our patented design provides both 2-D and 3-D profiles of the beam through more than one Rayleigh range. In our system, you always know what your beam looks like and where it is located.