Laser Beam Delivery Components

High Power Laser Beam Dump

Overview

High Power Beam Dumps are engineered to safely absorb and dissipate laser energy in systems greater than 500 watts. Compared to our standard beam dumps, these models feature a more robust thermal design with larger absorbers and higher flow water cooling. The internal geometry minimizes backscatter and thermal loading, making them ideal for high-duty-cycle laser applications where elevated power levels demand higher dissipation capacity.

Available Product Series

-

38mm Series

-

50mm Series

Compatible Laser Types

-

Collimated Input

Select the part number you need and click the button below to request a quote and more information.

Applications

Applications

High-power beam dumps—also known as laser beam traps or laser beam blocks—are essential in industrial and research environments where continuous, high-power laser energy must be safely dissipated.

These units are commonly used in:

-

Automated laser welding and cutting cells, where beam termination is required during idle cycles or system checks

-

Laser testing stations to safely measure or redirect high-power beams during diagnostics

-

R&D labs and optics test benches that work with multi-kilowatt fiber or CO₂ lasers

-

Laser safety systems, providing a secure endpoint when beams are switched off or diverted

Their water-cooled design and robust absorber geometry make them ideal for handling long-duration exposure at high power levels without degradation.

Product selection guidance

Selecting a Beam Dump

High-power beam dumps are available in just a few configurations, making selection straightforward. Each part number indicates three things:

-

Aperture Size

Choose 38 mm or 50 mm depending on your beam diameter and system layout. A good rule of thumb is 1.5× your beam diameter. -

Absorber Material

Brass-coated cone — best for high-power infrared lasers (1064 nm–10.6 µm)

Copper — ideal for UV and visible wavelengths (355–532 nm) -

Cooling Type

Water-cooled, high-power system — designed for up to 20 kW continuous use

If you're unsure which model fits your setup, contact us and we’ll help you pick the right option.

Laser Beam Dump Product Configurations

BD-38-H

38mm Series

Select part numbers and download CAD files

-

- Water-Cooled (Operating Pressure: 80PSI MAX.)

- Use in systems up to 2kW

- 38mm Clear Aperture

- Internal Cone Absorber

- 10mm O.D. Tube push-to-connect fittings provided

-

Part Number Absorber BD-38-H-B-WRecommended for 1070nm - 10.6µmBrass(coated)BD-38-H-C-WRecommended for 355nm - 532nmCopperSpecifications subject to change without notice

-

File Name File bd-38-h-b-w.zipDownload

BD-50-K

50mm Series

Select part numbers and download CAD files

-

- Water-Cooled

- Use in systems up to 20kW (1µm - 11µm)

- 50mm Clear Aperture

- Minimum coolant supply capacity for MAX operation >6.0 GPM (22.7 L/min)

- Liquid-Cooled Operating Pressure: 80PSI MAX. (5.5 Bar)

- 1/2" BSPT Inlet and Outlet Cooling Ports (12mm O.D. Tube push-to-connect fittings provided)

- 1/8 NPT Ports for customer-supplied sensors (Temperature, Pressure, etc.)

- Input Aperture mounting holes for use with 50mm Series components

-

Part Number Primary Surface Secondary Surface BD-50-KCSS

CopperStainless SteelSpecifications subject to change without notice

-

File Name File bd-50-k.zipDownload

Accessories

Laser Bezel Adaptors

A selection of bezel adapters to protect the beam path.

IR Laser Alignment Cards

Thermal sensitive CO2 alignment cards are used to align optical components to the laser beam axis.

Alignment Targets

Alignment targets make laser beam setup and optical alignment fast and repeatable. Available for all Haas LTI beam delivery sizes, they simplify system setup, troubleshooting, and maintenance.

Product Features

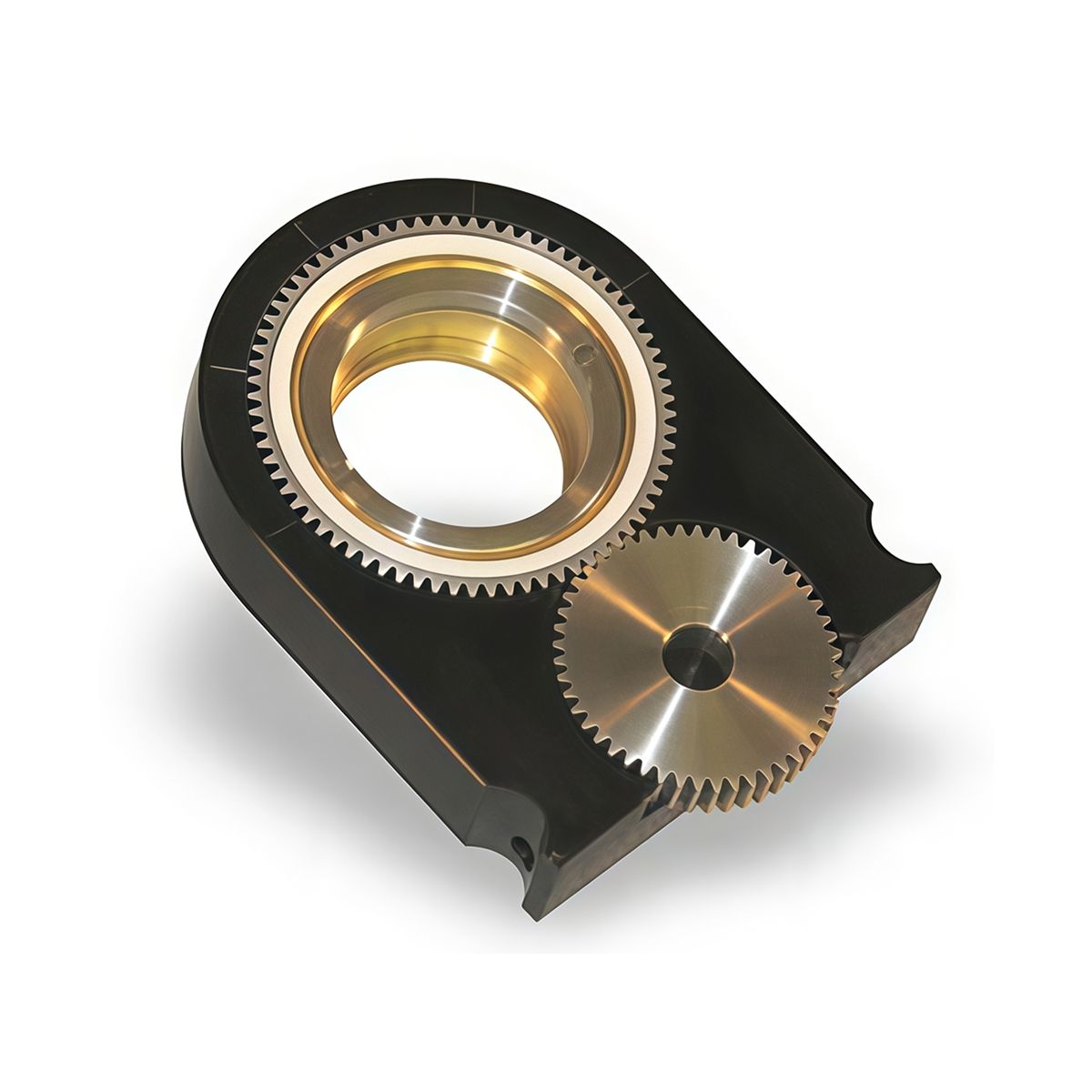

Billet aluminum construction

CNC machined from 6061 aluminum to give robust performance in demanding environments. Perfect for factories, production use, optical tables and prototyping.

High-efficiency thermal absorber

Robust internal core engineered to dissipate up to 20 kW of continuous laser power. Optimized geometry and materials minimize backscatter and handle extreme energy loads.

Integrated water cooling

Active cooling system ensures stable performance during high-duty-cycle or continuous-wave operation. Required for high-power lasers to prevent overheating.