Laser Beam Delivery Components

Beam Splitter

Overview

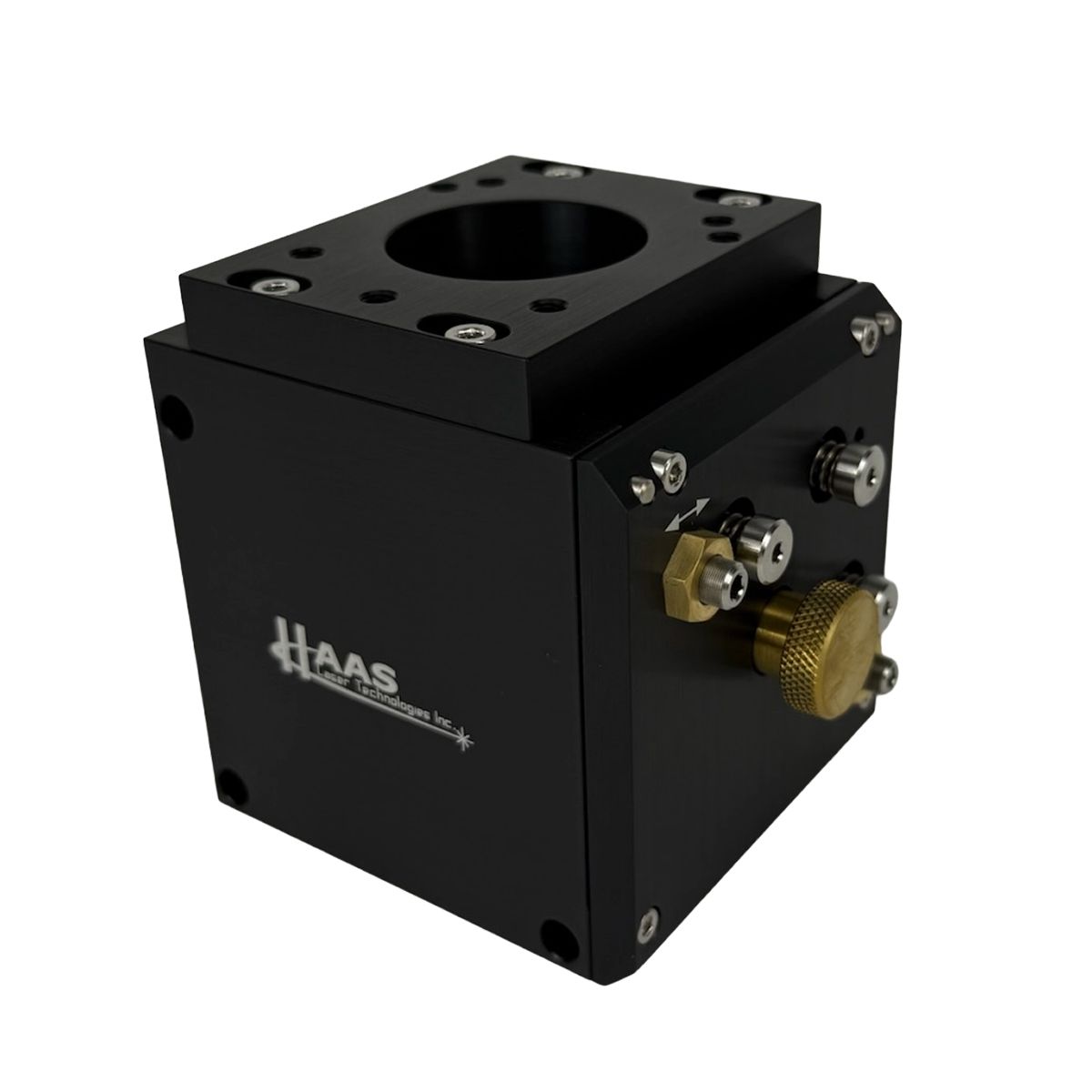

Haas kinematic beam splitters housings divide a single laser beam into two separate paths using a partially reflective optic mounted at 45 degrees. Part of the beam is reflected at a right angle, while the rest continues straight through. Each unit features a kinematic mirror holder for angular adjustment and is housed in a modular body compatible with Haas beam delivery components.

Beam splitter housings are available in a range of aperture sizes. The optic holder is designed to be compatible with all standard round beam splitter optics. Common uses include beam sampling, system redundancy, and directing a portion of the beam to diagnostics or secondary processes. They are suitable for both factory-floor installations and lab-based development work.

Available Product Series

-

19mm Series

-

25mm Series

-

38mm Series

-

50mm Series

Compatible Laser Types

-

Collimated Input

Select the part number you need and click the button below to request a quote and more information.

Applications

Applications

Haas beam splitters — also know as beam samplers, beam dividers, or splitter modules — are used in systems where a single laser beam needs to be distributed across multiple optical paths. By sending part of the beam to a secondary location, these components support a wide range of industrial and research applications.

In laser processing systems, beam splitters are commonly used to route a portion of the beam to a monitoring device, power sensor, or camera. This allows for real-time diagnostics, beam profiling, or safety verification without interrupting the main process. In dual-head or multi-station setups, beam dividers can be used to deliver laser power to multiple workstations from a single source, improving throughput and system efficiency.

In lab and R&D environments, beam splitter modules are often used for process development, optical experiments, or system testing. Their adjustable design allows users to easily tune the reflection angle, making them useful for prototyping new beam layouts on optical tables.

Common industries include semiconductor manufacturing, medical device production, aerospace and defense, and university research labs—anywhere a laser beam needs to be split, sampled, or redirected without compromising beam quality or alignment stability.

Product selection guidance

Specing a Beam Splitter

To select the correct beam splitter housing for your system, you'll need to choose the aperture size, optic diameter, and optic thickness. Haas beam splitters are designed to match the rest of your beam delivery system by series.

1. Choose Aperture Size

Match the aperture to your system's beam diameter and mechanical series:

-

BSK-19 – 19 mm series

-

BSK2-25 – 25 mm series

-

BSK2-38 – 38 mm series

-

BSK-50 – 50 mm series

We recommend selecting an aperture at least 1.5x your beam diameter to avoid clipping.

2. Select Appropriate Optic Diameter

3. Select Appropriate Optic Thickness

Product Configurations

BSK-19

19mm Series

Select part numbers and download CAD files

-

- ±2º Independent Orthogonal Mirror Adjustment

- 80 Pitch Adjustment Screws

- Accommodates Standard 25mm, 1" or 1.1" Diameter Beam Splitting Optics

- Face & Side Mounting Holes

- Suitable for All Wavelengths

- Sealed Design

- Anodized Aluminum Construction

- 19mm Clear Aperture

- Optics not included

-

Part Number Optical Diameter Optical Edge Thickness Mirror Suspension BSK-19-25020-LRecommended for Fused Silica optic substrates1.0in2.0mmLow ForceBSK-19-25020-S1.0in2.0mmStandardBSK-19-25030-LRecommended for Fused Silica optic substrates1.0in3.0mmLow ForceBSK-19-25030-S1.0in3.0mmStandardBSK-19-25040-LRecommended for Fused Silica optic substrates1.0in4.0mmLow ForceBSK-19-25040-S1.0in4.0mmStandardBSK-19-25050-LRecommended for Fused Silica optic substrates1.0in5.0mmLow ForceBSK-19-25050-S1.0in5.0mmStandardBSK-19-25060-LRecommended for Fused Silica optic substrates1.0in6.0mmLow ForceBSK-19-25060-S1.0in6.0mmStandardBSK-19-25064-LRecommended for Fused Silica optic substrates1.0in6.4mmLow ForceBSK-19-25064-S1.0in6.4mmStandardBSK-19-25M020-LRecommended for Fused Silica optic substrates25mm2.0mmLow ForceBSK-19-25M020-S25mm2.0mmStandardBSK-19-25M030-LRecommended for Fused Silica optic substrates25mm3.0mmLow ForceBSK-19-25M030-S25mm3.0mmStandardBSK-19-25M040-LRecommended for Fused Silica optic substrates25mm4.0mmLow ForceBSK-19-25M040-S25mm4.0mmStandardBSK-19-25M050-LRecommended for Fused Silica optic substrates25mm5.0mmLow ForceBSK-19-25M050-S25mm5.0mmStandardBSK-19-25M060-LRecommended for Fused Silica optic substrates25mm6.0mmLow ForceBSK-19-25M060-S25mm6.0mmStandardBSK-19-25M064-LRecommended for Fused Silica optic substrates25mm6.4mmLow ForceBSK-19-25M064-S25mm6.4mmStandardBSK-19-28020-LRecommended for Fused Silica optic substrates1.1in2.0mmLow ForceBSK-19-28020-S1.1in2.0mmStandardBSK-19-28030-LRecommended for Fused Silica optic substrates1.1in3.0mmLow ForceBSK-19-28030-S1.1in3.0mmStandardBSK-19-28040-LRecommended for Fused Silica optic substrates1.1in4.0mmLow ForceBSK-19-28040-S1.1in4.0mmStandardBSK-19-28050-LRecommended for Fused Silica optic substrates1.1in5.0mmLow ForceBSK-19-28050-S1.1in5.0mmStandardBSK-19-28060-LRecommended for Fused Silica optic substrates1.1in6.0mmLow ForceBSK-19-28060-S1.1in6.0mmStandardBSK-19-28064-LRecommended for Fused Silica optic substrates1.1in6.4mmLow ForceBSK-19-28064-S1.1in6.4mmStandardSpecifications subject to change without notice

-

File Name File bsk-19-s.zipDownload

BSK2-25

25mm Series

Select part numbers and download CAD files

-

- ±2º Independent Orthogonal Mirror Adjustment

- 80 Pitch Adjustment Screws

- Accommodates Standard 38mm (1.5in) Diameter Beam Splitting Optics

- Face & Side Mounting Holes

- Available for All Wavelengths

- Sealed Design

- Anodized Aluminum Construction

- 21.5mm Clear Aperture

- Optics not included

-

Part Number Optical Diameter Optical Edge Thickness Cooling BSK2-25-38030-N

38mm (1.5in)

3mm (.125in)

None

BSK2-25-38030-W

38mm (1.5in)

3mm (.125in)

WaterBSK2-25-38040-N

38mm (1.5in)

4mm

None

BSK2-25-38040-W

38mm (1.5in)

4mm

WaterBSK2-25-38050-N

38mm (1.5in)

5mm

None

BSK2-25-38050-W

38mm (1.5in)

5mm

WaterBSK2-25-38060-N

38mm (1.5in)

6mm

None

BSK2-25-38060-W

38mm (1.5in)

6mm

WaterBSK2-25-38064-N

38mm (1.5in)

.25in

None

BSK2-25-38064-W

38mm (1.5in)

.25in

WaterBSK2-25-38090-N

38mm (1.5in)

9mm

None

BSK2-25-38090-W

38mm (1.5in)

9mm

WaterBSK2-25-38095-N

38mm (1.5in)

9.5mm (.375in)

None

BSK2-25-38095-W

38mm (1.5in)

9.5mm (.375in)

WaterSpecifications subject to change without notice

BSK2-38

38mm Series

Select part numbers and download CAD files

-

- ±2º Independent Orthogonal Mirror Adjustment

- 80 Pitch Adjustment Screws

- Accommodates Standard 50mm or 2.0" Diameter Beam Splitting Optics

- Face & Side Mounting Holes

- Mounting hole pattern allows for easy interchangeability with BBK-38

- Sealed Design

- Anodized Aluminum Construction

- Water Cooled option available

- Water Cooling specs.: 0.5 Gal./min. (1.89 L/min.) Max., 80 PSI (5.5 Bar) Max.

- 32mm Clear Aperture

- Beam splitting optic not included

-

Part Number Optical Diameter Optical Edge Thickness Cooling BSK2-38-50050-N50mm5.0mmNoneBSK2-38-50050-W50mm5.0mmWaterBSK2-38-50064-N50mm.250inNoneBSK2-38-50064-W50mm.250inWaterBSK2-38-50095-N50mm.375inNoneBSK2-38-50095-W50mm.375inWaterBSK2-38-50100-N50mm10mmNoneBSK2-38-50100-W50mm10mmWaterBSK2-38-51050-N2.0in5.0mmNoneBSK2-38-51050-W2.0in5.0mmWaterBSK2-38-51064-N2.0in.250inNoneBSK2-38-51064-W2.0in.250inWaterBSK2-38-51095-N2.0in.375inNoneBSK2-38-51095-W2.0in.375inWaterBSK2-38-51100-N2.0in10mmNoneBSK2-38-51100-W2.0in10mmWaterSpecifications subject to change without notice

BSK-50

50mm Series

Select part numbers and download CAD files

-

- ±2º Independent Orthogonal Mirror Adjustment

- 80 Pitch Adjustment Screws

- Accommodates Standard 75mm or 3.0in Diameter Beam Splitting Optics

- Face & Side Mounting Holes

- Available for All Wavelengths

- Sealed Design

- Anodized Aluminum Construction

- Water Cooled option available

- Water Cooling specs.: 0.5 Gal./min. (1.89 L/min.) Max., 80 PSI (5.5 Bar) Max.

- 42mm Clear Aperture

- Optics not included

-

Part Number Optical Diameter Optical Edge Thickness Cooling BSK-50-75064-N75mm0.25inNoneBSK-50-75064-W75mm0.25inWaterBSK-50-75076-N75mm0.3inNoneBSK-50-75076-W75mm0.3inWaterBSK-50-75095-N75mm0.375inNoneBSK-50-75095-W75mm0.375inWaterBSK-50-75100-N75mm10mmNoneBSK-50-75100-W75mm10mmWaterBSK-50-75127-N75mm0.5inNoneBSK-50-75127-W75mm0.5inWaterBSK-50-76064-N3in0.25inNoneBSK-50-76064-W3in0.25inWaterBSK-50-76076-N3in0.3inNoneBSK-50-76076-W3in0.3inWaterBSK-50-76095-N3in0.375inNoneBSK-50-76095-W3in0.375inWaterBSK-50-76100-N3in10mmNoneBSK-50-76100-W3in10mmWaterBSK-50-76127-N3in0.5inNoneBSK-50-76127-W3in0.5inWaterSpecifications subject to change without notice

Accessories

Laser Bezel Adaptors

A selection of bezel adapters to protect the beam path.

Alignment Targets

Alignment targets make laser beam setup and optical alignment fast and repeatable. Available for all Haas LTI beam delivery sizes, they simplify system setup, troubleshooting, and maintenance.

Optic Cleaning Kit

Specifically designed for industrial laser systems, the Optic Cleaning Kit contains the proper tools and solutions to clean laser optics.

Mirrors

Our mirrors redirect laser beams at 45° with near-100% reflectivity. Options include visible-transmissive mirrors with AR coatings for camera integration. Specs available to guide selection.

Beam Combiners

Beam combiners align visible lasers with CO₂ systems by transmitting 10.6 µm and reflecting visible beams at 45°. Standard models are tuned for 633 nm, with options for 650 and 670 nm.

Beam Splitters

These 10.6 µm beamsplitters reflect a set percentage of energy at 45° AOI while transmitting the rest. Available with parallel or wedged surfaces, and in reflectance values from 4.5% to 50%.

Product Features

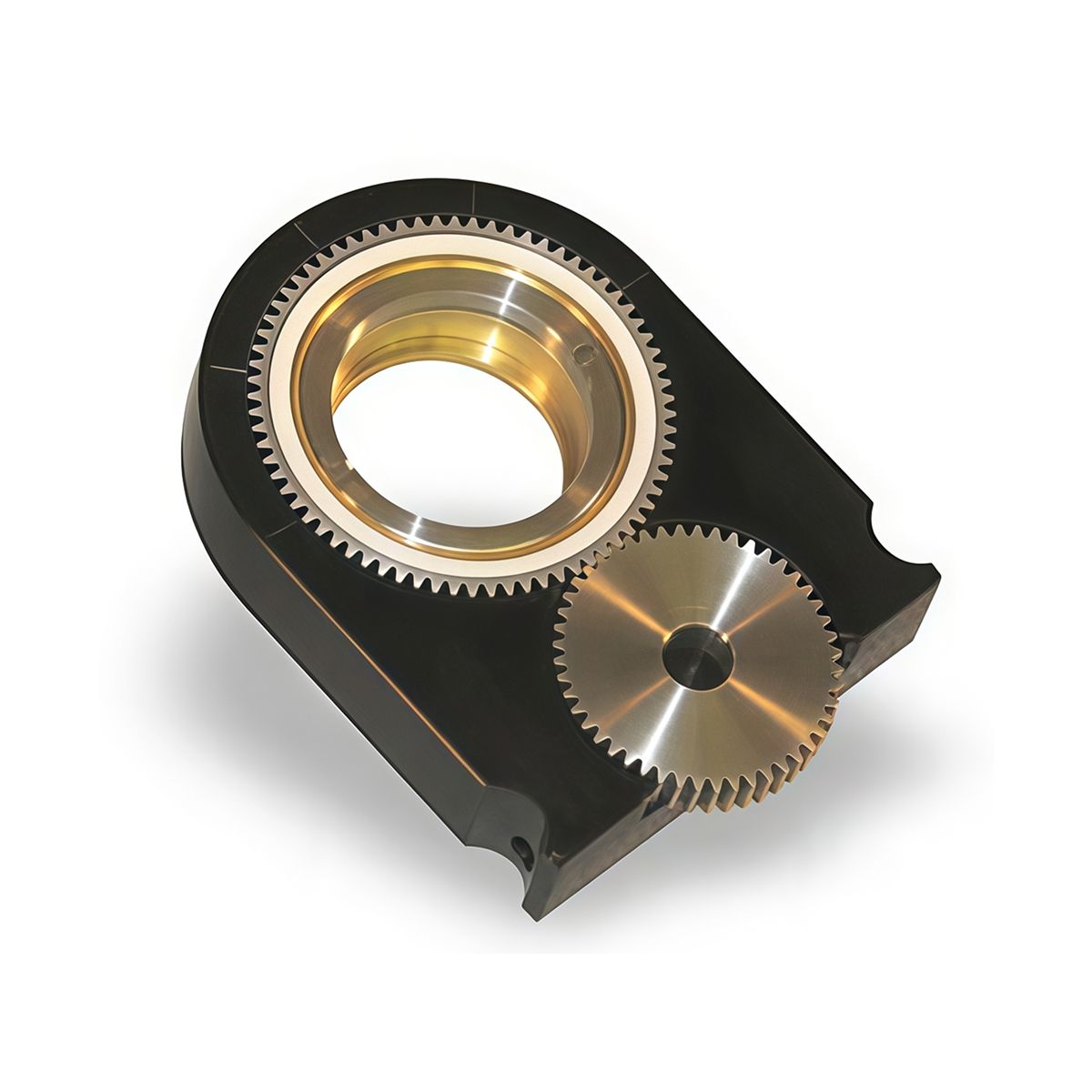

Billet aluminum construction

CNC machined from 6061 aluminum to give robust performance in demanding environments. Perfect for factories, production use, optical tables and prototyping.

Sealed optics & beam path

Our sealed optical beam path allows you to create a positive internal pressure to prevent dust and contaminants from entering the system. Great for dusty or dirty environments.

Fine adjustments in all directions

Using 80 pitch adjusters allows for infinite adjustment to create a perfectly centered beam. Paired with our alignment targets makes it easy to align multiple beam benders in series.