Tailored Solutions

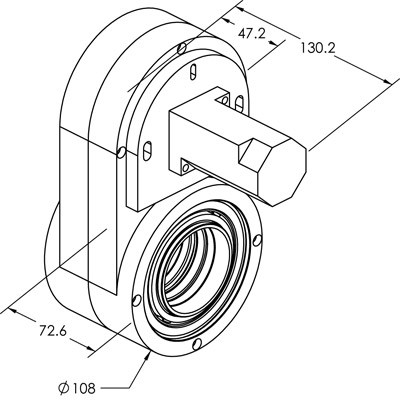

NeoScan Inverse Taper Module

Inverse taper in the NeoScan™ Scanner is achieved by rotating a tilted parallel plate about the optical axis while the scanner is operating. Ordinarily, a laser beam is passed through the central region of the focusing lens. The intensities at the focus are so high that the resulting hole drilled either has a small, positive taper or no taper but a bell-mouthed entrance. If the laser beam is shifted off axis, but parallel to the axis, the laser beam enters the material at a larger angle. It is this larger angle that achieves the inverse taper. By adjusting the tilt of the beam offset plate, different degrees of inverse taper can be realized.

NeoScanTM Inverse Taper Module Features

- Adjustable hole drilling taper

- > 10 degrees of inverse taper

- Works with any laser drilling system

- Drawing shown without mounting housing.

Contact us for information about this product

View other Tailored Solutions

- 50mm Laser Process Head Assembly

- 25mm Micro Machining Head Assembly

- Custom Capacitive Auto-Focus Nozzle Tip Assembly

- Beam Splitter with Dual Shutters

- FCTH-20 Form Cutting Trepan Head System

- Internal Aperture Wheel Assembly

- RLWS-10 Laser Wire Stripping System

- 6X Beam Splitter System

- Cassegrain Telescope

- Laser Enclosure with Articulated Arm System