Laser Beam Delivery Components

Beam Expanders

Overview

Fixed beam expanders are used to increase the diameter of a laser beam and improve its collimation. This helps reduce beam divergence and enables tighter focusing at long distances. Haas LTI offers beam expanders in 19 mm, 25 mm, and 38 mm aperture sizes, each designed for easy integration with standard beam delivery systems.

These expanders use a fixed optical configuration to achieve a consistent expansion ratio, making them ideal for applications that don’t require on-the-fly adjustment. Each system is aligned in-house for maximum stability and performance.

Available Product Series

-

19mm Series

-

25mm Series

-

38mm Series

Compatible Laser Types

-

Collimated Input

Select the part number you need and click the button below to request a quote and more information.

Applications

Applications

Fixed laser beam expanders play a critical role in precision laser processing where long working distances or fine focal spots are required. By increasing the beam diameter and improving collimation, these expanders reduce divergence and enable tighter, more consistent focus — especially important in high-precision or high-speed workflows.

In laser cutting systems, beam expanders help achieve narrower kerf widths and cleaner edges by allowing the focusing optics to concentrate the beam into a smaller, more defined spot. This results in greater precision, less thermal distortion, and improved edge quality on delicate or thin materials.

In drilling applications, such as those in aerospace or electronics manufacturing, expanders improve focus depth and allow for finer, more repeatable hole diameters. This is especially valuable when working with multilayer composites or heat-sensitive substrates.

In marking and engraving systems, expanded beams help reduce hot spots and improve consistency across the scan field, enhancing both visual quality and material compatibility. This is particularly beneficial for high-resolution text or detailed logos.

In medical device fabrication and semiconductor processing, where contamination control and ultra-fine feature sizes are critical, the improved collimation and focus stability of a beam expander ensures cleaner cuts and reduced debris.

Because Haas LTI's fixed beam expanders are built with rugged, aligned optics and no moving parts, they’re well-suited for high-volume production environments, robotic automation systems, and any process requiring long-term alignment stability.

Product selection guidance

Specing a Beam Bender

Haas beam benders are defined by three key parameters:

1. Aperture Size

Available in 19 mm, 25 mm, 38 mm, 50 mm, and 75 mm series.

Choose the aperture based on your beam diameter, with 1.5x margin recommended to avoid clipping.

2. Cooling Type

Depending on your system, a passively cooled option may not be enough. Use water cooling for above 100watt systems.

Another aspect to keep in mind is if you need any additional parts for water cooling such as a pump and reservoir.

3. Optional Features

Low Force: This uses a different design that put lets force on the optics. Generally recommened for fused silica optics.

Electrical Interlock: Reports if optic is installed via a single contact switch.

Product Configurations

BEC-19

19mm Series

Select part numbers and download CAD files

-

- Machined from Aluminum, Brass & Stainless Steel

- Fixed Overall Length for Easy Mounting

- Sealed Design

- Galilean Telescope Design Ensures Minimum Aberration

- Easily Removable Optics for Cleaning & Expansion Changes

- 1"-32 Mounting Thread, for Best Results Order with TMQ-19

- Available for All Wavelengths

- Optics are AR Coated for Specific Wavelength

- Custom Expansion Ratios Available

- Max. Output Aperture (Positive Expander) - 23mm

-

Part Number Expansion Wavelength Style BEC-19-1.5-10.6-S1.5x10.6μmShort BodyBEC-19-1.5-10.61.5x10.6μmStandardBEC-19-2.0-10.6-S2.0x10.6μmShort BodyBEC-19-2.0-10.62.0x10.6μmStandardBEC-19-2.5-10.6-S2.5x10.6μmShort BodyBEC-19-2.5-10.62.5x10.6μmStandardBEC-19-3.0-10.6-S3.0x10.6μmShort BodyBEC-19-3.0-10.63.0x10.6μmStandardBEC-19-3.5-10.63.5x10.6μmStandardBEC-19-4.0-10.64.0x10.6μmStandardBEC-19-5.0-10.6

5.0x

10.6μmStandardSpecifications subject to change without notice

-

File Name File bec-19-1-5-10-6-s.zipDownload bec-19-2-0-10-6.zipDownload bec-19-2-0-10-6-s.zipDownload bec-19-2-5-10-6.zipDownload bec-19-2-5-10-6-s.zipDownload bec-19-3-0-10-6.zipDownload bec-19-3-0-10-6-s.zipDownload bec-19-4-0-10-6.zipDownload bec-19-5-0-10-6.zipDownload bec-19-3-5-10-6.zipDownload

BEC-25

25mm Series

Select part numbers and download CAD files

-

- Machined from aluminum, brass & stainless steel

- Fixed overall length for easy mounting

- Sealed design

- Galilean Telescope design ensures minimum aberration

- Easily removable optics for cleaning & expansion changes

- Max. output aperture (Positive Expander) - 30mm

- For use with TMQ-25 Translation Mount

- Custom expansion ratios for multiple wavelengths available

Standard CO2 Expanders

Expansion Max. Input Beam Diameter Size Input Aperture Exit Aperture 1.5 ...... 20mm 22mm 30mm 2.0 ...... 15mm 22mm 30mm 2.5 ...... 12mm 22mm 30mm 3.0 ...... 10mm 22mm 30mm 3.5 ...... 8.6mm 22mm 30mm 4.0 ...... 7.5mm 22mm 30mm 5.0 ...... 6mm 22mm 30mm -

Part Number Expansion Wavelength Body Length BEC-25-1.5-10.6-S1.5x10.6µmShortBEC-25-1.5-10.61.5x10.6µmStandardBEC-25-2.0-10.6-S2.0x10.6µmShortBEC-25-2.0-10.62.0x10.6µmStandardBEC-25-2.5-10.6-S2.5x10.6µmShortBEC-25-2.5-10.62.5x10.6µmStandardBEC-25-3.0-10.6-S3.0x10.6µmShortBEC-25-3.0-10.63.0x10.6µmStandardBEC-25-3.5-10.63.5x10.6µmStandardBEC-25-4-10.64x10.6µmStandardBEC-25-5-10.65x10.6µmStandardSpecifications subject to change without notice

-

File Name File bec-25-1-25-10-6.zipDownload bec-25-1-5-10-6-s.zipDownload bec-25-2-0-10-6.zipDownload bec-25-2-0-10-6-s.zipDownload bec-25-2-5-10-6.zipDownload bec-25-2-5-10-6-s.zipDownload bec-25-3-0-10-6.zipDownload bec-25-3-5-10-6.zipDownload bec-25-4-0-10-6.zipDownload bec-25-5-0-10-6.zipDownload

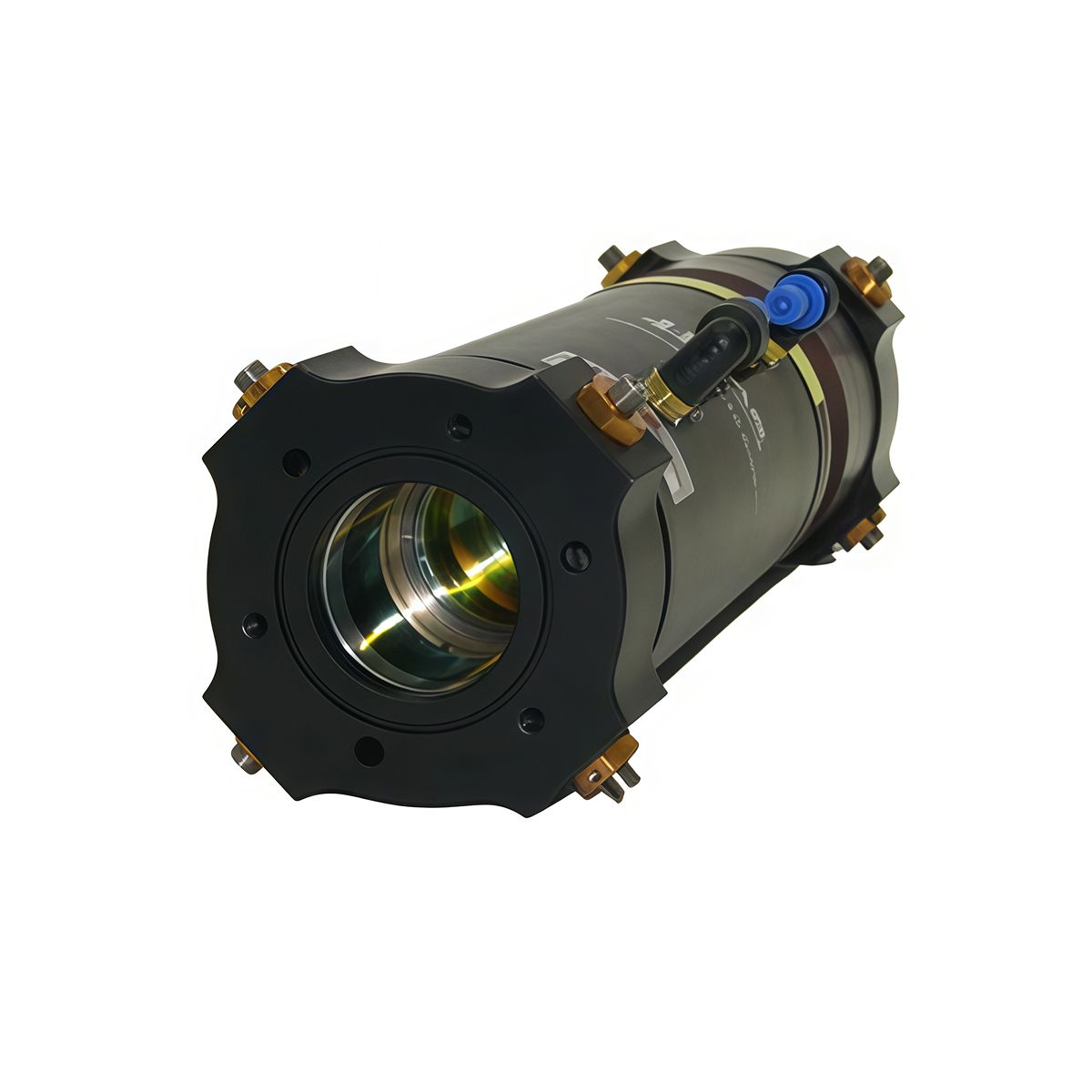

BEC-38

38mm Series

Select part numbers and download CAD files

-

- Machined from Aluminum, Brass & Stainless Steel

- Fixed Overall Length for Easy Mounting

- For best results order with TM-38 Translation Mount

- Sealed Design

- Galilean Telescope Design Ensures Minimum Aberration

- Easily Removable Optics for Cleaning

- Available for All Wavelengths

- Optics are AR Coated for Specific Wavelength

- Custom Expansion Ratios Available

- Max. Output Aperture (Positive Expander) - 34.9mm

- Optics Included

- Water Cooling included

- 6mm O.D. Tube Push-to-Connect Fittings for Water Cooling

-

Part Number Expansion Wavelength BEC-38-1.3-10.6-W1.3xCO2 (10.6um)BEC-38-1.5-10.6-W1.5xCO2 (10.6um)BEC-38-2.0-10.6-W2.0xCO2 (10.6um)BEC-38-2.5-10.6-W2.5xCO2 (10.6um)BEC-38-3.0-10.6-W3.0xCO2 (10.6um)BEC-38-3.5-10.6-W3.5xCO2 (10.6um)BEC-38-4.0-10.6-W4.0xCO2 (10.6um)BEC-38-5.0-10.6-W5.0xCO2 (10.6um)Specifications subject to change without notice

Accessories

Collimator/Expander Translation Mount

Translation mounts for laser beam expanders and collimators, allowing for fine X-Y positional adjustment to align the optical axis with minimal effort.

Alignment Targets

Alignment targets make laser beam setup and optical alignment fast and repeatable. Available for all Haas LTI beam delivery sizes, they simplify system setup, troubleshooting, and maintenance.

Product Features

Billet aluminum construction

CNC machined from 6061 aluminum to give robust performance in demanding environments. Perfect for factories, production use, optical tables and prototyping.

Sealed optics & beam path

Our sealed optical beam path allows you to create a positive internal pressure to prevent dust and contaminants from entering the system. Great for dusty or dirty environments.

Fine adjustments in all directions

Using 80 pitch adjusters allows for infinite adjustment to create a perfectly centered beam. Paired with our alignment targets makes it easy to align multiple beam benders in series.