Laser Beam Delivery Components

Standard Laser Beam Dump

Overview

Haas standard beam dumps are designed to safely absorb and terminate unused laser beams during operation, alignment, or system idle states. These units use a coated absorber housed in a machined body to dissipate laser energy without reflection or backscatter. Available in multiple aperture sizes, they integrate directly into Haas beam delivery systems and can be installed at test ports, process head bypasses, or beam stops.

Built for long-term use in both production and lab environments, these beam dumps provide a simple, reliable way to safely capture excess or redirected laser energy.

Available Product Series

-

19mm Series

-

25mm Series

-

38mm Series

-

50mm Series

Compatible Laser Types

-

Collimated Input

Select the part number you need and click the button below to request a quote and more information.

Applications

Applications

Standard beam dumps — also known as beam traps, laser beam absorbers, or beam stops — are used in nearly every laser system to safely capture unused or redirected laser beams. Whether for safety, alignment, or process control, they prevent stray reflections and reduce the risk of equipment damage or operator exposure.

In industrial systems, beam dumps are often mounted at the end of a beam path, inside bypass lines, or at test ports. They’re used during system startup, shutdown, or when switching between beam paths to capture the full output of high-power lasers. They’re especially common in laser cutting, welding, drilling, and materials processing setups where beam redirection is part of normal operation.

In labs and R&D, beam traps provide a safe and convenient way to block the beam during optical alignment or prototyping. Their compact footprint and passive cooling make them ideal for mounting on optical tables, breadboards, or inside experimental enclosures.

Because they operate passively with no moving parts, Haas beam dumps are a dependable, low-maintenance solution for any application where laser energy needs to be safely terminated.

Product selection guidance

Specing a Beam Dump

1. Choose Aperture Size

Match the dump to the aperture series of your beam delivery system:

-

BD2-19

-

BD-25

-

BD-38

-

BD-50

As a rule of thumb, choose an aperture that is 1.5× your beam diameter to prevent clipping or stray reflections.

2. Select Absorber Material

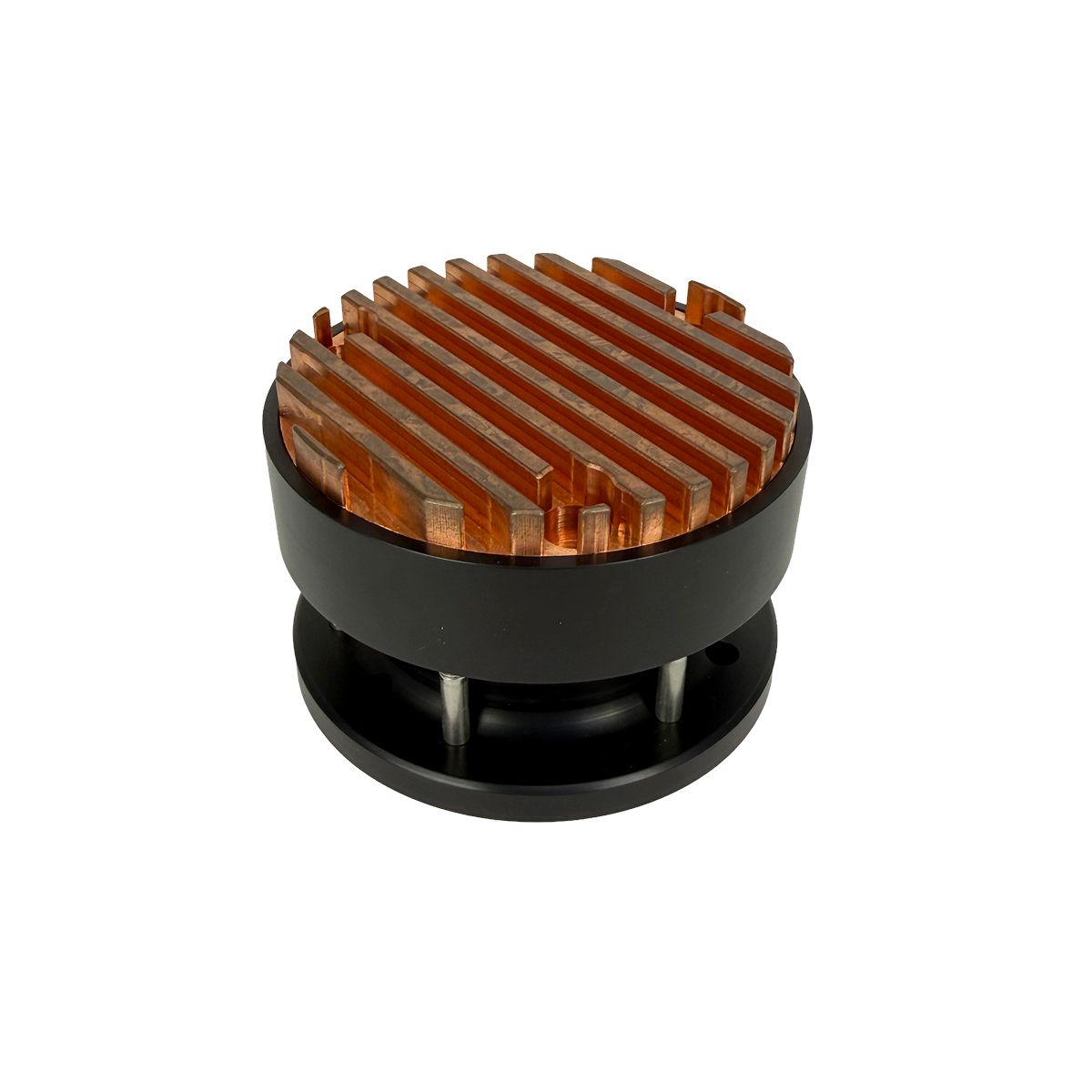

Haas beam dumps use internal conical absorbers designed to diffuse and absorb beam energy:

-

Brass-coated cones – Good for 1064 nm and IR wavelengths

-

Copper cones – Ideal for visible, UV, and green laser systems

Choose the absorber based on your wavelength range and desired durability.

3. Check Cooling Requirements

These are passively cooled models designed for moderate continuous power levels:

-

Air, ideal for power levels under 100watts

- Water, ideal for power levels between 100watts and 500watts

- For higher power beam dumps please see our high power beam dump product line

Laser Beam Dump Product Configurations

BD2-19

19mm Series

Select part numbers and download CAD files

-

- A Direct Replacement to BD-19 models

See comparison drawing in downloads. - Water or Air-Cooled

- Capacity: Water = 500W Air = 100W

- 18.5mm Clear Aperture

- Internal Cone Absorber or Coated Copper Wedge

- Liquid-Cooled Operating Pressure = 80PSI MAX

- Coolant Flow: 0.5 Gal./min. (1.9 L/min.)

- M6 x 1.0 Tap for fittings on water-cooled version

- 6mm O.D. Tube push-to-connect elbow fittings provided

- Various Absorber designs available

- 1"-32 Mounting Threads

- A Direct Replacement to BD-19 models

-

Part Number Absorber Cooling BD2-19-B-WRecommended for 1064nm - 10.6µmBrass, Coated, ConeWater, H2O : 500W maxBD2-19-B-ARecommended for 1064nm - 10.6µmBrass, Coated, ConeAir : for 100W or lessBD2-19-W-WRecommended for 1064nm -10.6µmCopper, Coated, WedgeWater, H2O : 500W maxBD2-19-W-ARecommended for 1064nm -10.6µmCopper, Coated, WedgeAir : for 100W or lessBD2-19-C-WRecommended for 355nm - 532nmCopper, Uncoated, ConeWater, H2O : 500W maxBD2-19-C-ARecommended for 355nm - 532nmCopper, Uncoated, ConeAir : for 100W or lessBD2-19-WC-WRecommended for 355nm - 532nmCopper, Uncoated, WedgeWater, H2O : 500W maxBD2-19-WC-ARecommended for 355nm - 532nmCopper, Uncoated, WedgeAir : for 100W or lessSpecifications subject to change without notice

BD2-19-B-W

BD-25

25mm Series

Select part numbers and download CAD files

-

- Water or Air-Cooled

- 500W Capacity. Water/500W - Air/100W

- 25mm Clear Aperture

- Internal Cone Absorber

- Liquid-Cooled Operating Pressure: 80PSI MAX.

- Coolant Flow: 0.5 Gal./min. (1.9 L/min.)

- M6 x 1.0 Tap for cooling

- 6mm O.D. Tube push-to-connect elbow fittings provided

- Various Absorber designs available

- 1 ¼" - 32 Mounting Thread

-

Part Number Absorber Cooling BD-25-B-WRecommended for 1070nm - 10.6µmBrass, Coated, ConeWater, H2O : 500W maxBD-25-B-ARecommended for 1070nm - 10.6µmBrass, Coated, ConeAir : for 100W or lessBD-25-C-WRecommended for 355nm - 532nmCopper, Uncoated, ConeWater, H2O : 500W maxBD-25-C-ARecommended for 355nm - 532nmCopper, Uncoated, ConeAir : for 100W or lessSpecifications subject to change without notice

BD-38

38mm Series

Select part numbers and download CAD files

-

- Water or Air-Cooled

- 500W Capacity. Water/500W - Air/100W

- 38mm Clear Aperture

- Internal Cone Absorber

- Liquid-Cooled Operating Pressure: 80PSI MAX.

- 1/8" BSPT Tap for cooling

- 6mm O.D. Tube push-to-connect elbow fittings provided

- Mounting hole pattern is compatible with other 38mm Series components

- Various Absorber designs available

-

Part Number Absorber Cooling BD-38-B-WRecommended for 1070nm - 10.6µmBrass, Coated, ConeWater, H2O : 500 watts maxBD-38-B-ARecommended for 1070nm - 10.6µmBrass, Coated, ConeAir : for 100 watts or lessBD-38-C-WRecommended for 355nm - 532nmCopper, Uncoated, ConeWater, H2O : 500 watts maxBD-38-C-ARecommended for 355nm - 532nmCopper, Uncoated, ConeAir : for 100 watts or lessSpecifications subject to change without notice

BD-50

50mm Series

Select part numbers and download CAD files

-

- Water or Air-Cooled

- 500W Capacity. Water/500W - Air/100W

- 50mm Clear Aperture

- Internal Cone Absorber

- Liquid-Cooled Operating Pressure: 80PSI MAX.

- 1/8" BSPT Tap for cooling

- 8mm O.D. Tube push-to-connect elbow fittings provided

- Mounting hole pattern is compatible with other 50mm Series components

- Various Absorber designs available

-

Part Number Absorber Cooling BD-50-B-WBrass, Coated, ConeWater, H2O : 500W maxBD-50-B-ABrass, Coated, ConeAir : for 100W or lessBD-50-C-WCopper, Uncoated, ConeWater, H2O : 500W maxBD-50-C-ACopper, Uncoated, ConeAir : for 100W or lessSpecifications subject to change without notice

Accessories

Laser Bezel Adaptors

A selection of bezel adapters to protect the beam path.

Locking Rings

Locking rings thread onto beam tubes and process heads to prevent components from moving.

Alignment Targets

Alignment targets make laser beam setup and optical alignment fast and repeatable. Available for all Haas LTI beam delivery sizes, they simplify system setup, troubleshooting, and maintenance.

Product Features

Billet aluminum construction

CNC machined from 6061 aluminum to give robust performance in demanding environments. Perfect for factories, production use, optical tables and prototyping.

High-performance absorber coatings

Internal cone surfaces are treated with wavelength-specific coatings to maximize absorption and minimize back reflection across UV to IR ranges.

Air or water-cooled options

Flexible cooling configurations allow use with both low-power and high-power lasers. Water cooling recommended for continuous or high-duty-cycle applications.